MassChallenge’s mission is clear: Catalyze a startup renaissance. The organization’s model serves as the largest startup accelerator in the world to help early-stage entrepreneurs succeed with no equity required and financial prizes awarded. When entrepreneurs are empowered to challenge old conventions and create new value, a startup renaissance begins. Enter MassChallenge (MC). With roots in Boston, the program is expanding globally to Tel Aviv and London. Every year, 2,200+ startups apply to participate, with only 128 eager candidates accepted.

Within the MC walls, entrepreneurs are in a supportive network with the resources they need to launch their diverse ventures. Workshops for raising funds, training on navigating the legal space, and professional mentoring from 400 prominent business volunteers have been consistent (sometimes referred to as a “mini MBA for entrepreneurship”). However, a working laboratory to physically test products was lacking. The MADE@ Hardware Lab at the Boston location opened this past March out of a need to support the physical development of products.

MADE@ Hardware Lab is located at MassChallenge Boston.

How Does Instron® Fit?

Instron is committed to delivering the highest quality, leading-edge technologies and services designed to push the boundaries of research and quality control through its testing products. With an extensive history of partnering with Fortune 500 companies and universities across the globe to provide quality assurance, it only seemed fitting for Instron to support the MADE@ initiative. As a result, Instron equipment is now available to these inspiring entrepreneurs. Before taking a product to market, thorough research is required to determine safety and effectiveness. Where Instron testing systems evaluate the mechanical properties of materials and structures using tensile, compression, flexural, fatigue, impact, dynamic, torsional and multi-axial loading, startups can now complete product manuals and confirm if their products comply with international standards.

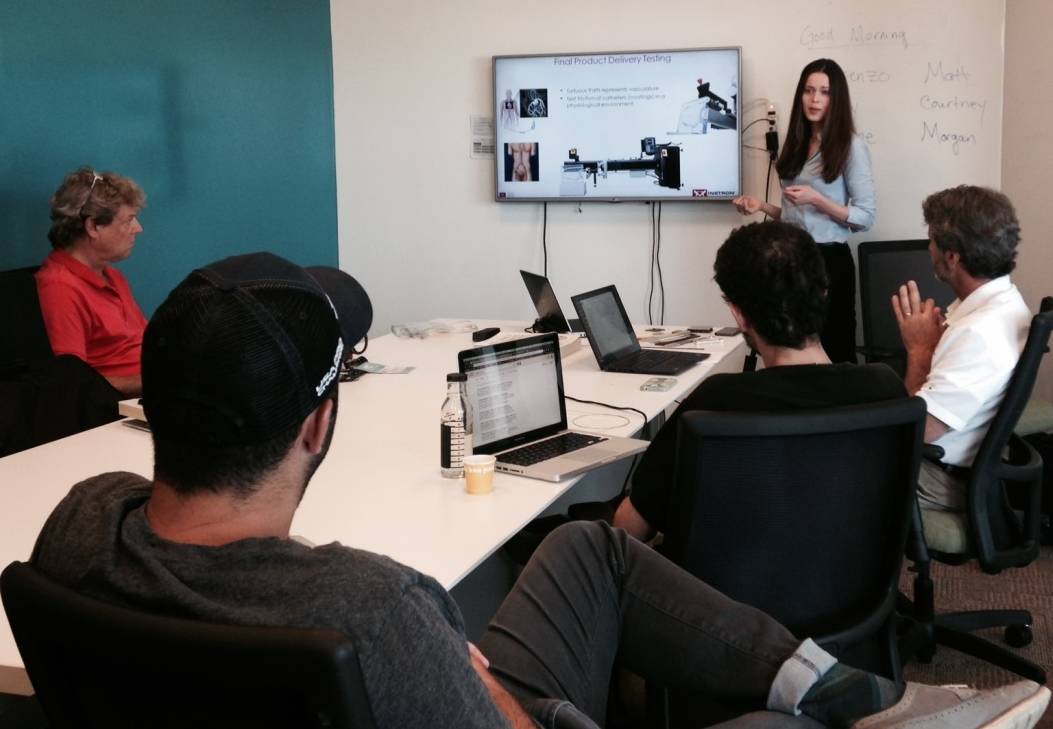

While visiting the MassChallenge facility, Instron had the pleasure of meeting a few of MC’s entrepreneurs and offering tips on best practices for materials testing. As each application is unique, the versatility of Instron’s universal testing systems can meet the various prototyping needs.

Instron Applications Engineer Elayne Gordonov provides interactive education on materials testing.

LaunchPad Medical, LLC

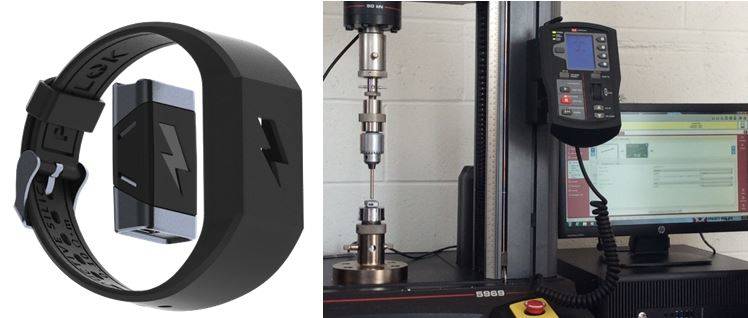

LaunchPad Medical is the innovative group behind Tetranite™, a synthetic bone adhesive that both repairs bone and stabilizes metal implants. This revolution will allow innovative surgical techniques and cost-effective treatments to improve patient care and access. Tetranite™ combines the utility of strength, biocompatibility and affordability, making it commercially superior. LaunchPad Medical is initially focusing on the dental market, with hopes to expand across the entire bone health space as research and quality advances.

Mike Brown, LaunchPad Medical consultant, observes Tetranite™ undergoing a tension test.

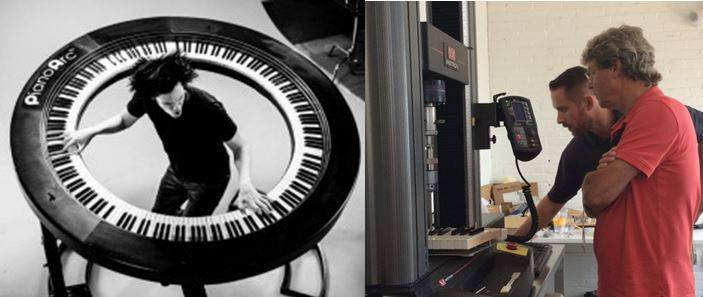

PianoArc is reshaping the musical keyboard industry, literally. When the team quickly constructed a circular keyboard controller for an international music tour, word got out, and demand has been rising. With a US patent and IP in the works, the Edison Award finalists are looking to refine their invention for the international performing keyboard market. Besides its fascinating design, the keyboard’s sensing technologies allows it to “speak” to the computers in ultra-fine grained resolution.

Dave Starkey, a pioneer in MIDI and lead engineer at PianoArc, reviews the impact of force on the keys.

With its innovative wearable band, Pavlok promises to break a bad habit in five days or less. Pavlok’s design integrates behavioral training techniques, "zaptic" hardware, and tracking software to kick habits like smoking, nail biting, and being unproductive. Sending electronic sensations, at varying levels, the wearable device provides real-time, continuous conditioning. Hundreds have successfully broken bad habits due to Pavlok’s technology.

The Difference Is Measurable

Partnering with MassChallenge, Instron is proud to be supporting this center of excellence in the early stages of prototyping and progress. The hope is that the developments made by these engineers and researchers continue to make positive impacts on the global market. The current record has seen that over the past five years, 89% of startups from MassChallenge are still active.

Here’s to continued success for the MassChallenge entrepreneurs!