In recent years, composites fatigue testing has rapidly moved from a research interest to a critical commercial requirement, but the cost - in terms of machine time - remains a significant challenge to commercial testing The wind energy industry has led this demand, but aerospace and automotive sectors are defining their own needs in this area and fatigue performance is expected to become an additional qualification requirement for their composite materials and assemblies.

Cyclic loading of composites dissipates a considerable amount of energy, which results in “self-heating” of specimens. Not only can this cause specimen temperature to rise by more than 20 °C in the wrong test conditions, but this varies during the course of a test, and is rarely repeatable from one specimen to the next. Standard practice demands a single low frequency (typically 3 to 5 Hz) for all tests in order to avoid overheating, but that means very long and expensive test schedules. Temperature has a major effect on results since the performance of these materials is far more temperature sensitive than that of metals. Unfortunately, the fact that specimens generate heat internally means that there is always an offset from the surrounding environment, so temperature rise is not actually controlled even when working in a chamber. In response to this demand, Instron® developed a unique control solution that typically gives more than a 25% time saving for a composite S-N dataset and can maintain specimen temperature to within ± 0.5 °C of a specified target.

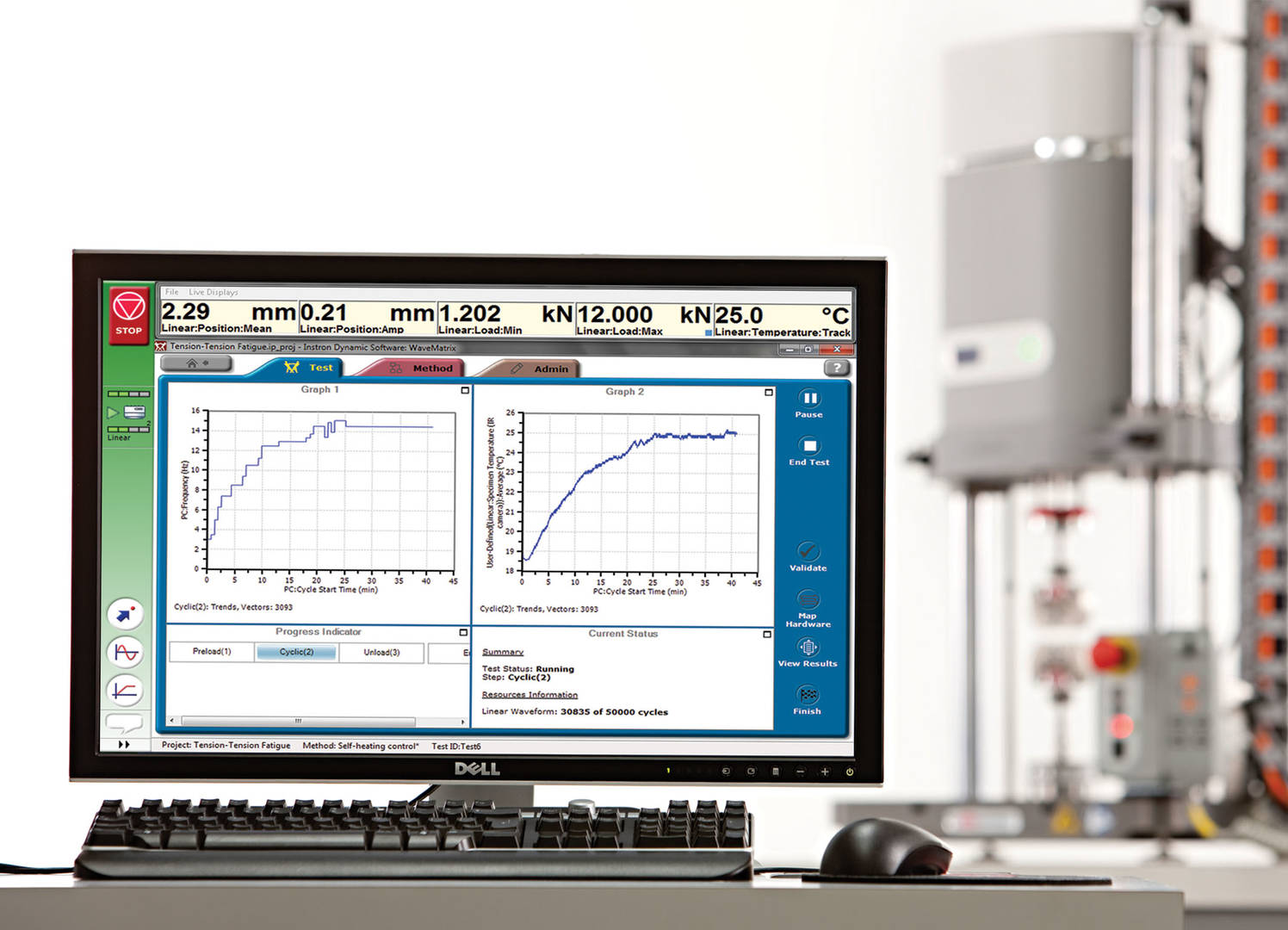

Specimen Self-Heating Control in WaveMatrix™ dynamic test software accepts an input of specimen temperature, which is used in a sophisticated outer-loop control of test frequency*. The user sets the target test temperature and the system then automatically adjusts the live test frequency (within user-specified limits) to achieve it. This means that at low stress levels, where each specimen survives millions of cycles, the frequency can be increased to greatly reduce the test time. Conversely, at high stress levels (where each test is several orders of magnitude shorter) the frequency must often be reduced to prevent excessive heating, but this has little effect on the overall time for the S-N dataset.

Instron asked the UK National Composites Certification and Evaluation Facility at Manchester University (NCCEF) to assess the comparability of results by producing an S-N data set using their standard method followed by a complete repetition on the same batch of material using Specimen Self-Heating Control. In two separate trials on commercial epoxy pre-preg materials with carbon fiber and e-glass fibre reinforcement (respectively), NCCEF found that the logarithmic data fitting coefficients were almost identical and that specimen temperature variation was reduced from ± 4 °C during a test to a range of less than ± 0.5 °C. On the carbon fiber reinforced material, the batch time was reduced by 15 machine-days on a total time of 55 days.

For the test laboratory struggling to fulfil demand for composites S-N curve generation, Specimen Self-Heating control offers exceptional value – the price of this small software extension can enable each machine to handle over 35% more tests.

*Thermocouples or non-contact transducers can be used.