電子機器とマイクロエレクトロニクスの試験

75年以上の実績があり、75,000台以上の試験システムを世界中に提供してきたインストロンは、材料試験業界のグローバルリーダーとして知られています。インストロンは、何十年にもわたって、家電業界屈指の開発者たちと提携し、長寿命の急速充電バッテリー、折り曲げが可能な革新的なディスプレイ、タッチ機能が向上したデバイス、携帯性を向上させる高密度パッケージなど、新しい技術がもたらす試験の課題に取り組んできました。この協業の一環として、柔軟性を考慮し試験システムを設計しました。これにより、将来にわたって最先端の技術を試験するために、当社のシステムを容易に適合させることが可能になります。

推奨アクセサリー

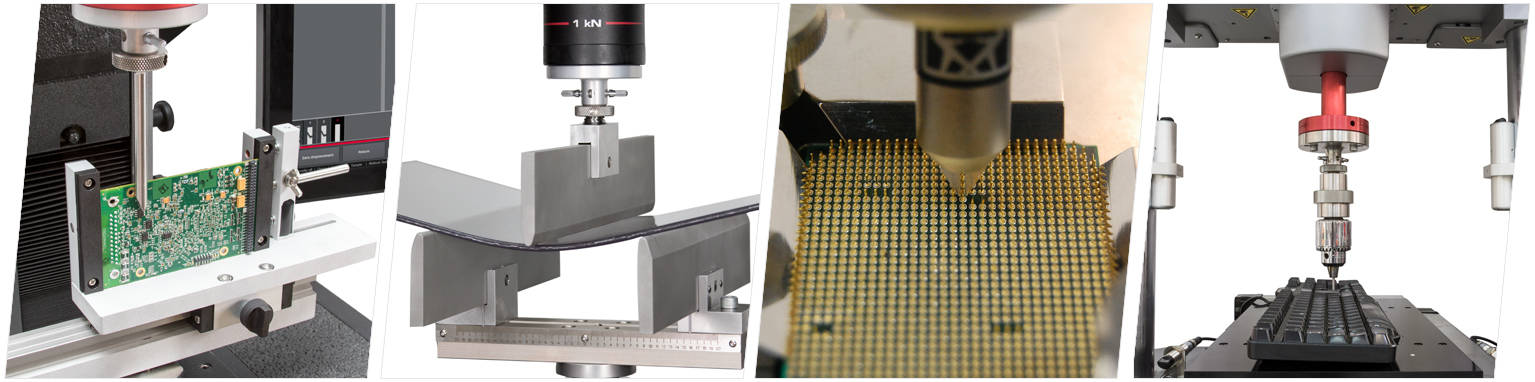

幅広い電子機器とマイクロエレクトロニクス部品を試験するために

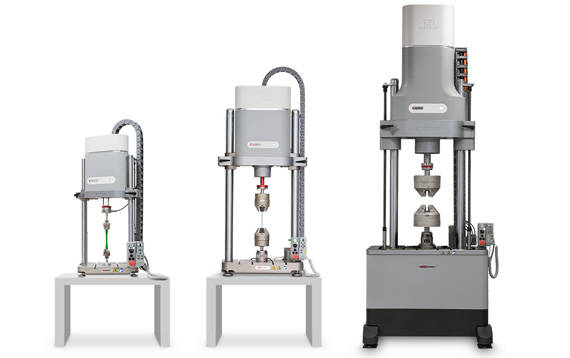

インストロンは、電子機器およびマイクロエレクトロニクス製造業者の、低荷重から中荷重の試験ニーズに対応するため、あらゆる種類の電気機械式万能試験システムを提供しています。68SCシングルコラムシステムは、0.02 Nから5 kNまでの荷重容量で試験ができ、68TMデュアルコラムシステムの荷重容量範囲は最大で50 kNです。これらのシステムは、引張、圧縮、曲げ、剥離、せん断などの試験を実施するための、幅広いアクセサリーを備えています。インストロンのエンジニアソリューション部門では、ユニークな試験片の形状やサイズにも対応できるカスタム治具の開発にも取り組んでいます。デュアルコラム試験機は特注幅に対応し、温度環境試験用の加熱槽および冷却槽を装備できます。

| よりスマートな試験 | |

|---|---|

| 1) | 1台の装置ですべての製品を試験 ロードセル容量の1/1000までの精度を誇るクラス最高のロードセル |

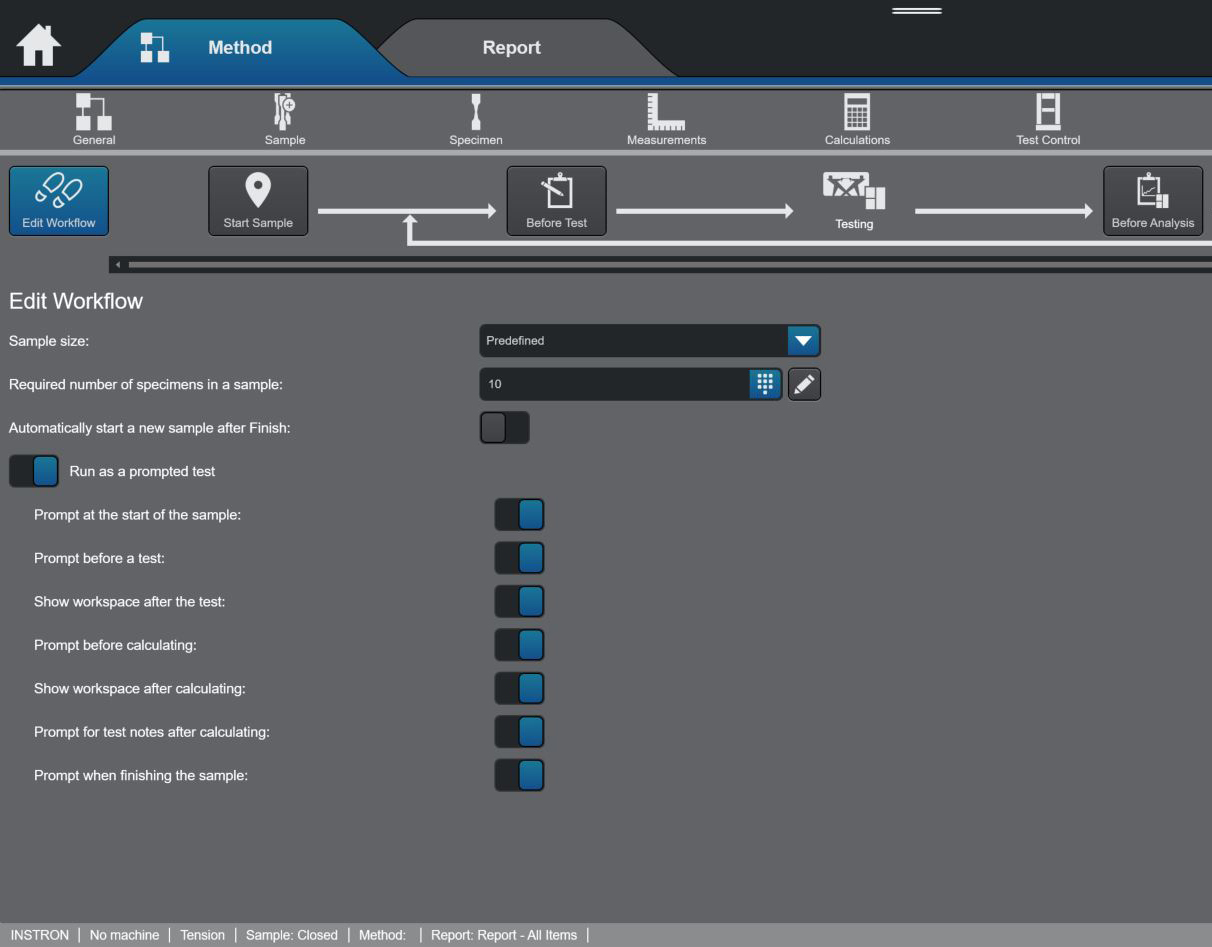

| 2) | シンプルな操作 タッチ操作のBluehill® Universalソフトウェアでは、段階的指示に従うことで、前試験工程を誘導します。 |

| 3) | 試験における一貫性 Bluehill Universalの試験メソッドは、システム間および試験室間で容易に移行可能 |

| 4) | 以下の温度で試験可能 標準ソリューションは-100°C~+350°Cで、デュアルコラム試験フレームと互換性あり |

| 5) | 試験処理能力の向上 標準的な試験システムには、さまざまな自動化ソリューションを装備可能 |

| 6) | あらゆる種類および形状の試験片をグリップ 小さいマイクロエレクトロニクスアセンブリから最終製品まで、あらゆる製品の試験に対応する、交換可能な幅広いグリップと治具を用意 |

| 7) | 優れた適合性 カスタム治具に対応したシステム構築が可能 |

電子機器やマイクロエレクトロニクスの試験では、適応性が重要です。電子機器やマイクロエレクトロニクスはサイズや形状が豊富にあり、技術や消費者の好みの進化とともに頻繁に変化します。インストロンのシステムは、このような製品の機械特性を試験するために理想的な、幅広いグリップ、治具、アクセサリーと互換性があるため、特注治具にも容易に対応できます。

電子機器用アクセサリーの表示大量の試験を管理しやすくするには、一部自動化を導入します。これには、自動試験片測定装置から、自動XYステージ、そして完全に自動化されたロボット試験システムなど、あらゆるものが含まれます。経験豊富な自動化エンジニアの専門チームが、お客様と協力して、スループット要件を満たすシステムを開発します。

自動化ソリューションを表示マイクロエレクトロニクスやバッテリーなど、数多くの電子機器は、使用中に極端な温度にさらされます。メーカーにとって重要なことは、幅広い条件下での性能と安全性の要因を把握しておくことです。恒温槽では、-100°Cから+350°Cまでの温度で材料や製品の機械特性を試験できます。これらはBluehill Universalで制御し、急速に加熱および冷却することができるため、時間を削減でき処理能力を向上することができます。

恒温槽を表示する1か所の試験室で試験を行う場合でも、グローバルなサプライチェーンで多くの試験室に分散して行う場合でも、一貫性を保つことが重要です。Bluehill Universalソフトウェアでは、あらゆるシステムで試験メソッドを作成し、他の試験システムや同様の試験を行っている試験室と簡単に共有できるため、試験プロセスにおける管理と信頼性を高めることができます。

推奨システム

電子機器とマイクロエレクトロニクスにとって最も一般的な試験なタイプを実行するには

インストロンの卓上型万能試験機は、ASTM、ISO、およびその他の業界標準に準じて、材料、コンポーネントおよび製品に対して引張、圧縮、曲げ、剥離、せん断、その他の機械試験を行います。

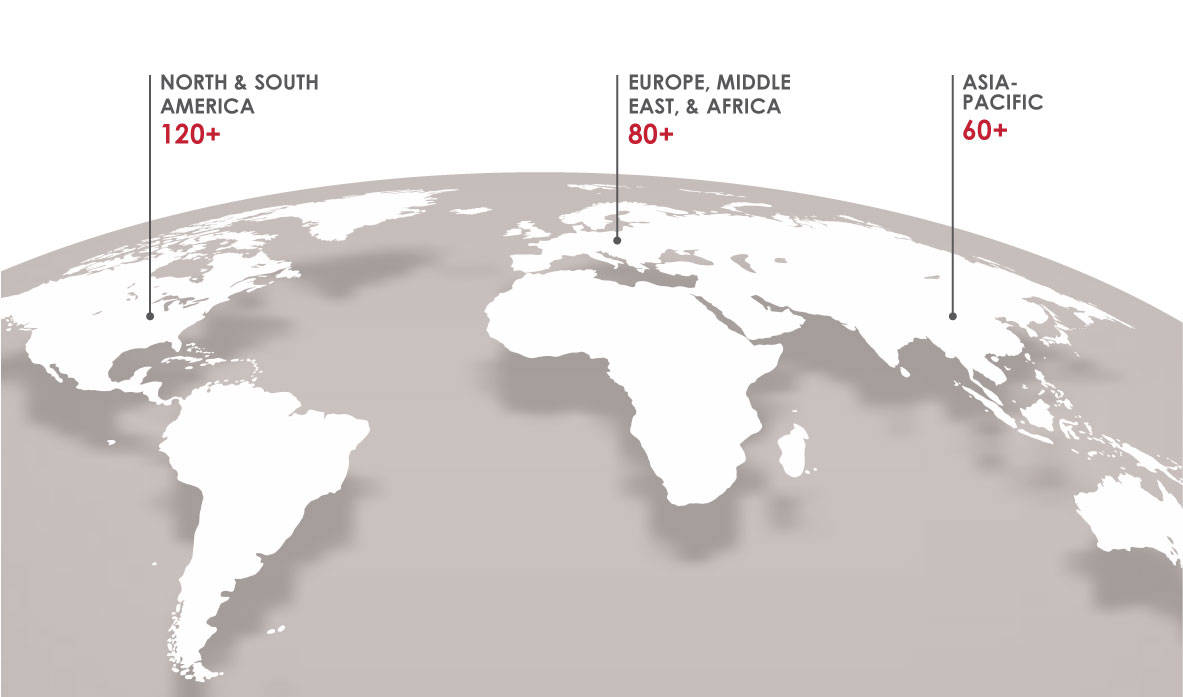

インストロンは世界中にサービスおよびサポートチームを配置し、お客様の所在地に関係なく、投資を維持できるよう支援いたします。お客様の試験機が最高の効率で稼働できるようインストロンシステムについて幅広いトレーニングを受けた250人以上の認定サービススタッフが世界中でサポートを行います。当社のエンジニアは、お客様の質問に対する回答、トレーニングの提供、システムの設置、既存の装置の修理とアップグレード、NISTにトレーサブルな校正と検証サービスの提供、お客様の装置がグローバルな試験規格に準拠しているかどうかの確認を行います。