Efficiency of Sheet Metal Testing

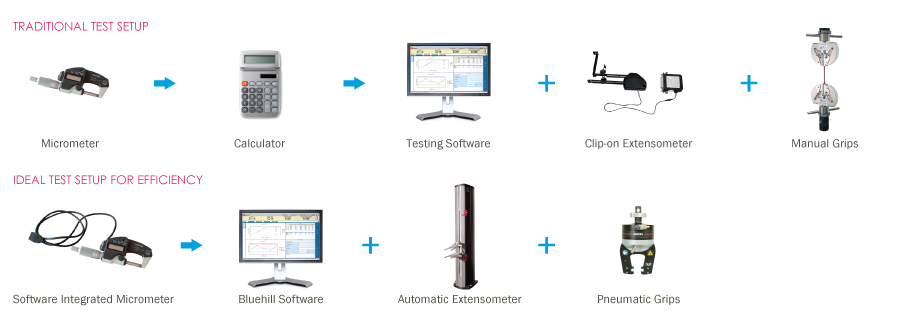

Globally, testing of sheet metal material is typically performed using a ‘traditional’ testing setup requiring a large amount of operator input. By utilizing some cost-effective changes, the efficiency of your testing regime can be greatly improved.

Using the latest Bluehill® Universal software, small modifications can be made to the testing protocol to gain incremental improvements. These could include creating a prompted test method to ensure only valid information is prompted for each test, minimizing wasted time needed to monitor or change non-value inputs.

Alternatively, integrating new or existing specimen measuring devices to work autonomously with the software instead of manually inputting values can save a great deal of time.

Switching from manual grips to either pneumatic or hydraulic grips will automate the gripping process. This significantly reduces the time it takes to close the upper and lower grip, and also ensures less variation in test results are caused by operators manually clamping each grip.

Automatic extensometers can save a large amount of time for each test since they require no manual setup between tests. Some extensometers may need to be removed during the test to prevent damage to the device. Therefore, time savings will also be achieved by using an automatic device that is designed to remain on the specimen through fracture or automatically removed.

The graphic below demonstrates a typical test cycle time comparing only the effect of extensometer choice:

Struggling to justify new purchases? Talk to Instron® to see where the most cost-effective changes could be made with your existing equipment.