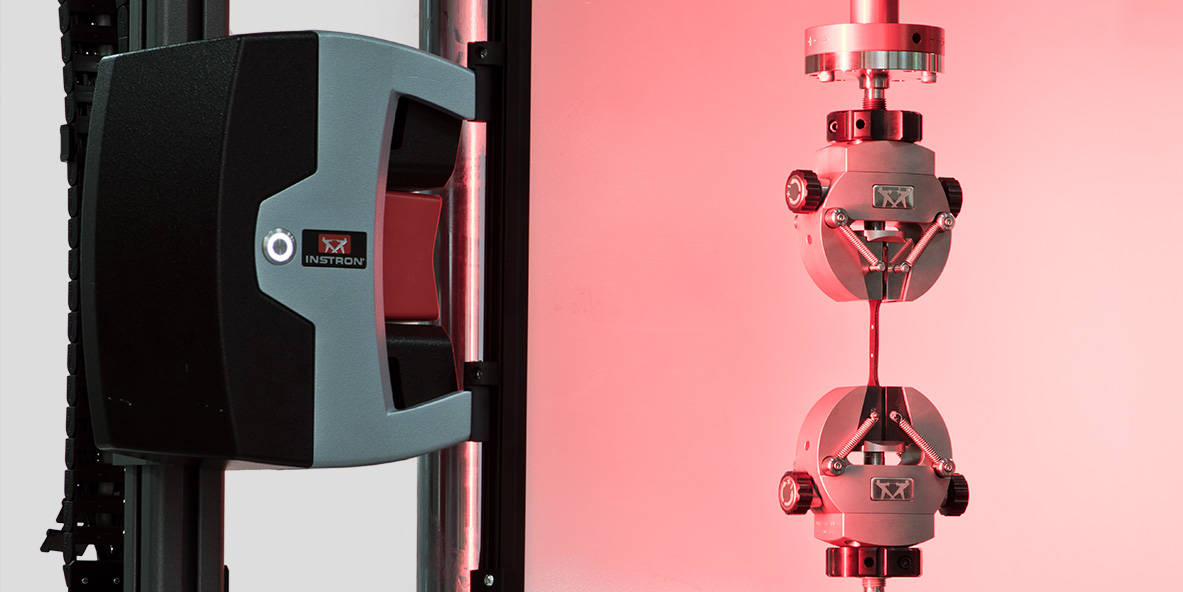

AVE 2 Dynamic | Low Force Applications

Revolutionary Strain Control

Increased flexibility

- Reduce associated costs of calibrating multiple replacement devices and trust your annual AVE 2 calibration test after test.

- single device offering a far superior range of Gauge Length & Travel compared to contacting extensometry. Reduced lab storage space and maintenance.

- A single non-contacting device suitable for both Static & Fatigue Testing requirements.

Intuitive Usability

- Improved consistency with a single testing procedure, easier, quicker and less skill required in preparing specimen for strain measurement.

- Remove human error in the process related to the attaching and reliable set up of a contacting device with automation of an AVE 2. Reduce set-up time and costs.

- AVE 2 eliminates the need to worry about different methods for maintaining gauge contact.

Impressive Performance

- Can't get the strain data needed for a clip on extensometer? The AVE 2 offers more confidence in your results.

- Non-contacting extensometry removes the possibility of premature specimen failure caused by clip on devices, which can be detrimental to a business's reputation.

- Maintain accurate strain control even on tricky specimens for long term tests.

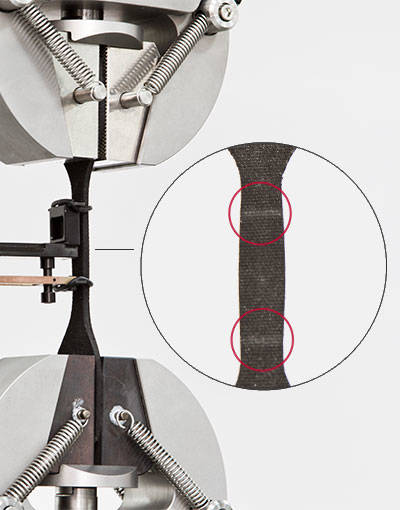

Understanding the Effect of Knife Edges on the Specimen Life of Compliant Materials

- Extensometer resonance could prevent you from testing at certain frequency ranges, introducing unwanted movement on the specimen, bringing your results in to question.

- Extensometer knife edges can cause damage to your compliant material, shortening specimen life and influencing failure mode and location.

- Mounting clip on extensometers to compliant specimens can be tricky and time consuming, with machine operators often wasting valuable time getting it right.

- Traditional clip on extensometers may have limited travel, which reduces the flexibility of your cyclic testing when recording strain data from compliant specimens.