MATERIALS TESTING FOR AEROSPACE APPLICATIONS

Testing for the aerospace industry demands high precision equipment combined with excellent laboratory practices and robust traceability. Instron systems are designed to provide reliable, repeatable measurements using high-quality equipment, with a wide range of grips and fixtures that allow precision adjustment of alignment to facilitate easier compliance with testing standards and accreditation bodies. Instron's calibration laboratory can also provide on-site verification and calibration for both transducer measurements and mechanical alignment that are internationally accredited by NVLAP and are directly traceable to national reference standards at NIST and NPL.

Instron has provided materials testing equipment to the aerospace sector for more than 75 years. As such, we recognize the origins of our customers’ demands for repeatability, reproducibility in round-robin testing, and overall audit-worthiness of their testing processes. Instron continues to engage with standardization and research meetings in order to stay in touch with evolving requirements and to offer the best support to the community.

Complying WITH NADCAP AND OTHER STANDARDS

Instron’s global service organization is uniquely positioned to support the calibration and verification needs of the aerospace industry, helping you to achieve Nadcap compliance in your lab. In addition to force, strain, speed, and displacement calibration, Instron’s factory-trained field service engineers can perform accredited alignment services with traceability, ensuring accurate and reliable test results. Instron’s calibration laboratories are Nadcap compliant and familiar with the standards that your laboratories are held to, allowing us to be a partner in understanding the calibration requirements that support your quality management systems. Additionally, as an active participant in Nadcap user group meetings and through access to Nadcap’s eAuditNet website, our calibration laboratories have access to the various standards and checklists needed for proper development and delivery of our calibration services.

Composite materials are widely used in the aerospace industry, and they are finding increasing use in primary structures, including fuselage and wings. Globally there has been a shift from metals to composites driven by the industry need to provide more fuel-efficient aircraft through lighter, more efficient products, which minimise aviation’s impact on the environment. Characterization of the properties of composite materials for aerospace applications requires a range of tests under different loading conditions often at non-ambient temperatures. For critical applications, more complex tests are required to determine their durability under service conditions e.g., Fatigue and Compression After Impact (CAI). Efficient testing of composite materials in compliance with approved standards and the requirements of auditing bodies such as Nadcap is demanding in terms of equipment and personnel. The process is made easier by an integrated approach to the testing machine set up and the use of testing software incorporating pre-defined test methods and traceability.

- Learn More About Composites Testing

- View Composites Testing Accessories

- Learn About Compression After Impact Testing

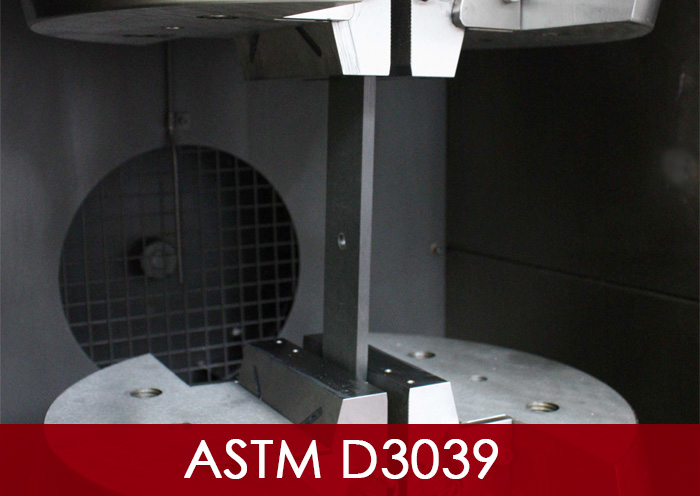

ASTM D3039 Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials

ASTM D3039 Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials

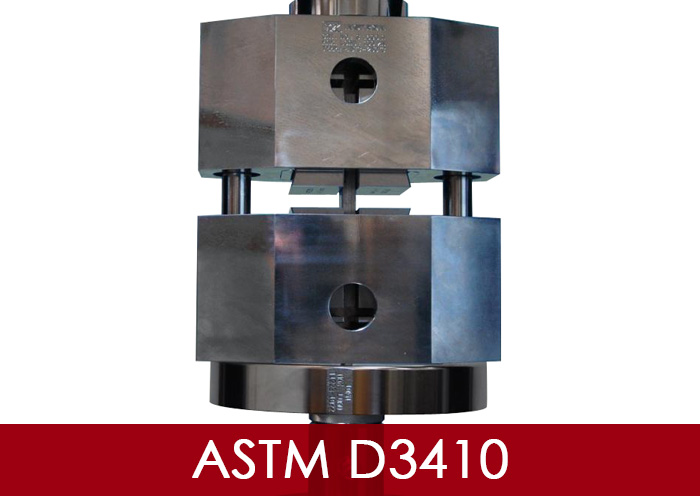

ASTM D3410 Measuring the Compressive Strength of Polymer Matrix Composites

ASTM D3410 Measuring the Compressive Strength of Polymer Matrix Composites

ASTM D7137 Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates

ASTM D7137 Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates

ASTM D5766 Open-Hole Tensile Strength of Polymer Matrix Composite Laminates

ASTM D5766 Open-Hole Tensile Strength of Polymer Matrix Composite Laminates

ISO 527-4 Tensile Properties of Isotropic and Orthotropic Fiber-Reinforced Plastic Composites

ISO 527-4 Tensile Properties of Isotropic and Orthotropic Fiber-Reinforced Plastic Composites

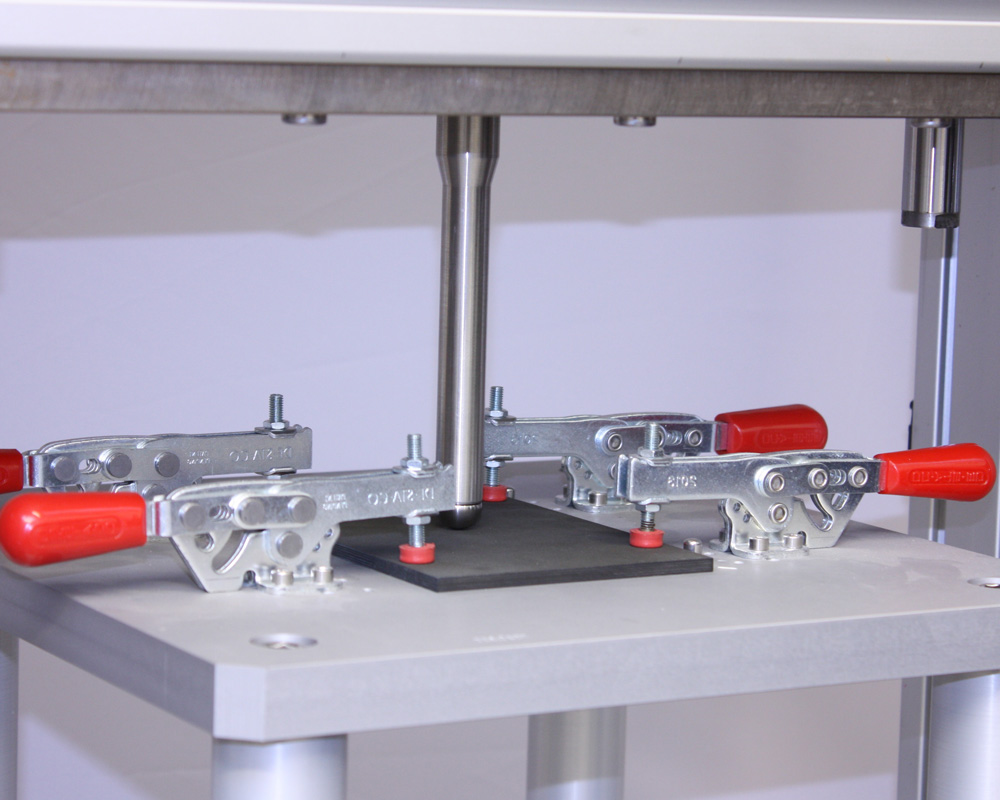

ASTM D7136/D7136M-05 Measuring Damage Resistance of Composite to Impact Event

ASTM D7136/D7136M-05 Measuring Damage Resistance of Composite to Impact Event

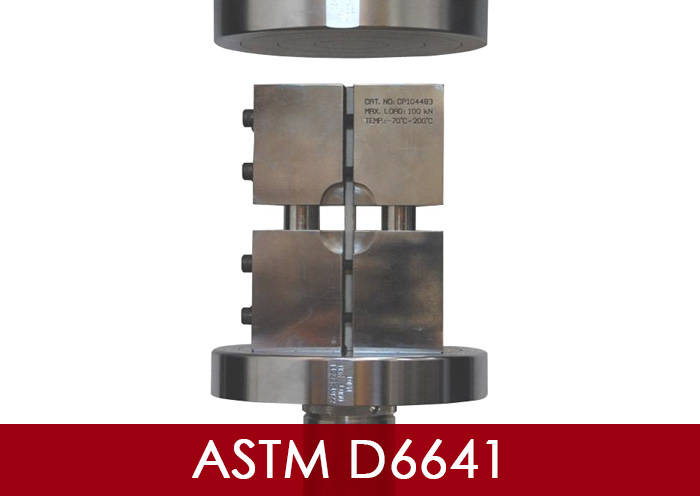

ASTM D6641 - Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture

ASTM D6641 - Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture

EN 2597 Carbon Fiber Reinforced Plastics. Unidirectional Laminates. Tensile Test Perpendicular to the Fiber Direction

EN 2597 Carbon Fiber Reinforced Plastics. Unidirectional Laminates. Tensile Test Perpendicular to the Fiber Direction

EN 2561:1995 Carbon Fiber Reinforced Plastics — Unidirectional Laminates — Tensile Test Parallel to the Fiber Direction

EN 2561:1995 Carbon Fiber Reinforced Plastics — Unidirectional Laminates — Tensile Test Parallel to the Fiber Direction

ASTM D5961 - Bearing Response of Polymer Matrix Composite Laminates

ASTM D5961 - Bearing Response of Polymer Matrix Composite Laminates

ASTM D6484 Open Hole Compressive Strength of Polymer Matrix Composite Laminates

ASTM D6484 Open Hole Compressive Strength of Polymer Matrix Composite Laminates

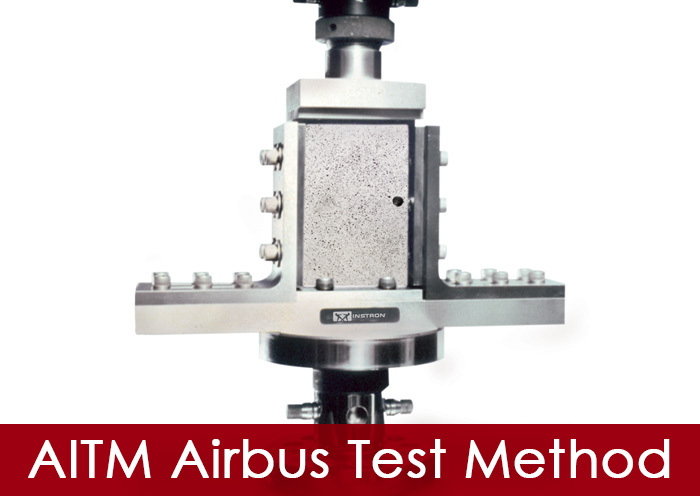

AITM Airbus Test Method for Determination of Compression Strength After Impact

AITM Airbus Test Method for Determination of Compression Strength After Impact

BSS 7260 Post-Impact Compressive Strength of Composite Laminates

BSS 7260 Post-Impact Compressive Strength of Composite Laminates

ISO 14125 Flexural Properties of Fiber-Reinforced Plastic Composites

ISO 14125 Flexural Properties of Fiber-Reinforced Plastic Composites

ISO 14126 In-Plane Compressive Properties of Fiber-Reinforced Plastic Composites

ISO 14126 In-Plane Compressive Properties of Fiber-Reinforced Plastic Composites

ISO 14129 In-Plane Shear Stress/Shear Strain Response

ISO 14129 In-Plane Shear Stress/Shear Strain Response

ISO 14130 Determination of Apparent Interlaminar Shear Strength by Short-Beam Method

ISO 14130 Determination of Apparent Interlaminar Shear Strength by Short-Beam Method

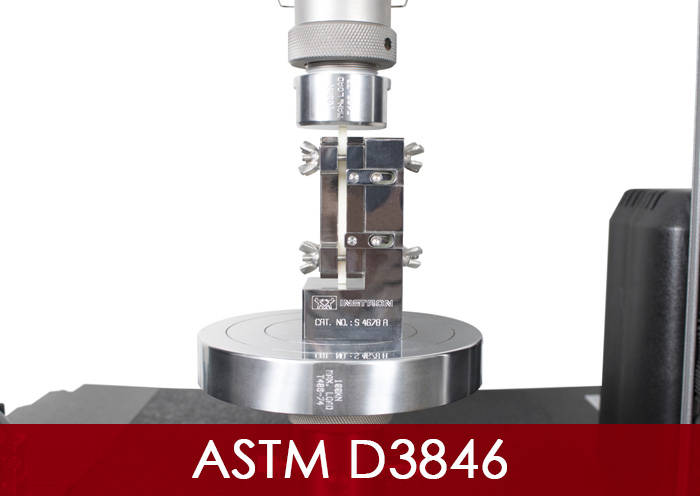

ASTM D3846 In-Plane Shear Strength of Reinforced Plastics

ASTM D3846 In-Plane Shear Strength of Reinforced Plastics

ASTM D4018 Standard Test Methods for Properties of Continuous Filament Carbon and Graphite Fiber Tows

ASTM D4018 Standard Test Methods for Properties of Continuous Filament Carbon and Graphite Fiber Tows

Aerospace structures rely on specially engineered metal alloys to perform safely and reliably in the most challenging environments both terrestrial and extraterrestrial. These alloys are subjected to extreme conditions such as high temperature, pressure, and stress, making mechanical testing an essential part of the quality control process. Aerospace engineers require repeatable testing and dependable data to optimize for design and material selection of all aerospace components, and that is particularly true for the metal structures that keep aircraft airborne and on time.

2xxx and 7xxx series alloys are the most common aluminum grades in aerospace manufacturing and are selected for their high strength-to-weight ratio. However, joining operations of both metals require precise controls and verification. Custom fixturing is important for improving throughput of welded components. Titanium alloys, such as 6Al-4V, are also valued for their high strength-to-weight ratio and commonly used in aerospace structure applications throughout the aircraft. The impressive holding capacity of titanium components also means that a great deal of energy is released during specimen failure. This can degrade the condition of low-quality testing frames and extensometers; however, Instron’s product offering is robustly engineered specifically to handle the high shock loads of even the strongest materials.

Mechanical testing is crucial for ensuring the reliability, safety, and efficiency of metal aircraft components. Instron’s solutions are designed to deliver dependable data for the most challenging aerospace metals to advance your design optimization, process development, and quality control initiatives.

Learn More About Metals Testing

The commercial aerospace industry is under pressure to develop engines that are increasingly more powerful and efficient. This has led to significant advances in both the super alloy materials used in these engines and the techniques used to manufacture them. The aggressive environments these components must operate within, with extremely high requirements for safety and durability, has led to a variety of advanced test techniques being developed and refined over the years.

Test results are required to be accurate and comparable between laboratories and the industry is continuously seeking to further reduce sources of potential errors, putting increasing demands on the suppliers of the test equipment. Instron continues to work with the aerospace industry and standards bodies to create a wide range of products and techniques to reduce this variability whilst pushing the boundaries of reducing test time through automation.

ASTM E21 Elevated Temperature Tension Tests of Metallic Materials

ASTM E21 Elevated Temperature Tension Tests of Metallic Materials

EN 2002-2 Aerospace Series. Metallic Materials. Test Methods Tensile Testing at Elevated Temperature.

EN 2002-2 Aerospace Series. Metallic Materials. Test Methods Tensile Testing at Elevated Temperature.

While the materials used in the manufacturing of aerospace vehicles is continuously evolving through the introduction of lightweight composites and additive manufacturing, the use of fasteners, nuts, and rivets throughout the vehicle body continues to be utilized as the primary assembly medium. Because these fasteners and rivets must withstand extreme environmental exposure and high stress levels, it is critical that these components are routinely tested against stringent quality standards from both international testing agencies and aerospace-specific organizations such as ASTM and Nadcap.

Tensile, Compression, Flexure

Universal testing systems can be equipped with a wide range of accessories to perform static tests when you need to determine the tensile, compressive, flexure, and shear properties of composites in ambient and non-ambient conditions.

Learn More

Impact Test

Designed for R&D and advanced quality control, Instron's drop weight impact testing systems are used to determine the energy required to break or damage a material from a specific height and with a specific impact energy and velocity.

Learn More

High Temperature Fatigue

Thermomechanical fatigue and electro-thermal mechanical testing systems simulate the complex effects of thermal cycling combined with mechanical loading, experienced by gas turbines and similar equipment during operation.

Learn More ASTM E8 Tension Testing of Metallic Materials

ASTM E8 Tension Testing of Metallic Materials ASTM A370 Mechanical Testing of Steel Products

ASTM A370 Mechanical Testing of Steel Products ISO 6892-1 Tensile Testing of Metallic Materials

ISO 6892-1 Tensile Testing of Metallic Materials KIc Fracture Toughness to ASTM E399

KIc Fracture Toughness to ASTM E399 JIc Fracture Toughness to ASTM E1820

JIc Fracture Toughness to ASTM E1820 ASTM F606 Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets

ASTM F606 Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets NASM 1312-13 Fastener Double Shear Testing

NASM 1312-13 Fastener Double Shear Testing