AVE 2 Dynamic | High Force Applications

Revolutionary Strain Control

Protect Your Investment

- The AVE 2 non-contacting video extensometer is isolated from the shock loading associated with high energy specimen failures. This guarantees that the life of your strain measurement device is not shortened with every test.

- Eliminate your maintenance spend on replacing high cost 'consumable' devices which no-longer perform reliably due to damage sustained during repeated high energy specimen breaks. Consolidate multiple transducers into one strain measurement device.

- Reduce associated costs of calibrating replacement devices. For a much wider variety of specimen types, you can trust your annual AVE 2 calibration test after test from the first specimen to the last.

More Efficient Testing

- Using the AVE 2 is quicker and more repeatable than using a clip-on extensometer. Consistency between technicians and faster test setup will result in more time spent testing specimens and less time setting up tests.

- A single high energy specimen break could potentially damage a traditional strain measurement device. This can lead to machine downtime. With AVE 2 you don't need to worry about machine downtime or supporting a range of backup transducers.

- Unlike traditional travel limited devices, the AVE 2 can test a wide range of specimen sizes and deflections with a single transducer. This means you will spend less time managing your inventory and simplify operator training.

Confidence in your Data

- Remove complexity and reduce human error in your test setup procedure by eliminating the need to reliably and repeatdly attach a contacting device to your specimen test after test.

- Can you tell when your clip on device has been damaged? Have your results been affected by shock loading? Trust the strain data generated from your AVE 2 all year round, test after test, from the first specimen to the last.

- Do you choose not to record strain data for your specimens? What might you be missing? The AVE 2 offers an easy way to collect strain data for a wide variety of specimens without impacting your specimen life.

Understanding the Effect of High Energy Specimen Failure on your Measurement Device

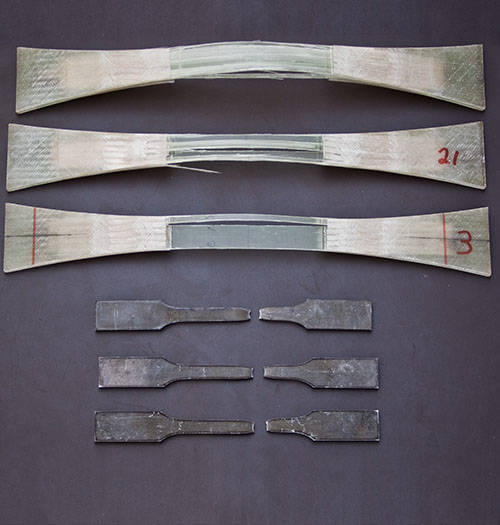

- Traditional metal specimens tend to yield steadily during their fatigue life. Necking of the specimen occurs gradually and the energy that is released at break is mostly converted into heat energy.

- In comparison a composite coupon has a much less predictable failure mode. The specimen may not show signs of yielding or necking during its fatigue life and then suddenly and catastrophically fail.

- A typical composite failure will transmit damaging forces through to a contacting strain measurement device in the form of shock loading. This in turn may damage the device itself and its ability to accurately measure strain.

If you want to protect your strain measurement device from damaging shock loads then contact us to discuss your non-contacting strain application today.

Contact Us to Discuss Your AVE 2 Application!