High Strain Rate VHS Systems

High Speed Testing up to 25 m/s

Many materials exhibit different behaviors under various strain rates, i.e. they have strain rate dependent properties. Characterizing these dynamic properties across a wide range of velocities becomes very important in applications where components are exposed to high strain rates, especially on investigating material failure and also identifying the most optimal design for weight.High strain rate testing machines have helped industries to predict material behavior, which in turn helps the design of many components that are exposed to high strain rates during its life cycle. Whether it is in the landing gear on aircraft, the crash impact of a road vehicle or even the cord strings when a parachute is opened, all of these examples involve one or more components of a product that are subjected to high strain rate impact. These components require safety and industry standards to be met in order to compete in the industry. Therefore, a high strain rate testing machine with reliable operations and accurate data acquisition is essential in designing safe and functional products and verifying the validity of the computer simulation tools, e.g. car crash simulation.

Available Models

|

|

||||

| Configuration | 2-Column High-Stiffness Load Frame with Actuator in Upper Crosshead | 4-Column High-Stiffness Load Frame with Actuator in Upper Crosshead |

|||

|

Frame Specifications

|

VHS 35/50 - 20

|

VHS 40/50 - 20

|

VHS 65/80 - 20 (25)

|

VHS 160/100 - 20

|

|

| Daylight Opening (Maximum Between Table and Crosshead)

|

1975 mm (78 in) | 1515 mm (60 in) | 1400 mm (55 in) | 1500 mm (59 in) | |

| Stall Force1 (Static Load Capacity)

|

±35 kN (±7.9 kip) | ±40 kN (±9 kip) | ±65 kN (±15 kip) | ±160 kN (±36 kip) | |

| Maximum Impact Load1 (Including Inertia Force of Piston Rod)

|

±50 kN (±11 kip) | ±50 kN (±11 kip) | ±80 kN (±18 kip) | ±100 kN (±22 kip) | |

| Maximum Velocity | 20 m/s | 20 m/s | 20 m/s (Optional 25) | 20 m/s | |

| Nominal Actuator Stroke (Includes 50mm buffer zones on each end)

|

600 mm (24 in) | 300 mm (12 in) | 300 mm (12 in) | 300 mm (12 in) | |

| Lift and Locks | Hydraulically-Powered Lifts and Locks | Hydraulically-Powered Lifts and Locks | |||

| Load Measurement System | Piezoelectric load washer and patented2 Dynacell™ fatigue-rated load cell supplied for calibration of piezoelectric load washer | Piezoelectric load washer and patented2 Dynacell™ fatigue-rated load cell supplied for calibration of piezoelectric load washer | |||

| Operating Pressure | 280 bar (4000 psi) | 280 bar (4000 psi) | |||

| Frame Weight (Approximate Guidance Only)

|

2500 kg (5512 lb) | 2500 kg (5512 lb) | 2900 kg (6390 lb) |

5300 kg (11700 lb) | |

| Dimensions (With Enclosure)

|

1660 x 1420 x 4150 mm3 (65 x 56 x 163 in3)* | 1660 x 1420 x 3350 mm3 (65 x 56 x 132 in3)* | 1660 x 1420 x 3350 mm3 (65 x 56 x 132 in3)* | 1660 x 1420 x 3550 mm3 (65 x 56 x 140 in3)* | |

| Literature | LEARN MORE | LEARN MORE | |||

*Dimensions are correct for the enclosure when supplied without environmental chamber.

1) Note that static and dynamic performance of the actuator is subject to change with specimen type and velocity, please consult Instron for further details

2) US Patent Number 6508132

3) Width x Depth x Maximum Height with crosshead raised to highest position, note that dimensions are subject to change without notice

2) US Patent Number 6508132

3) Width x Depth x Maximum Height with crosshead raised to highest position, note that dimensions are subject to change without notice

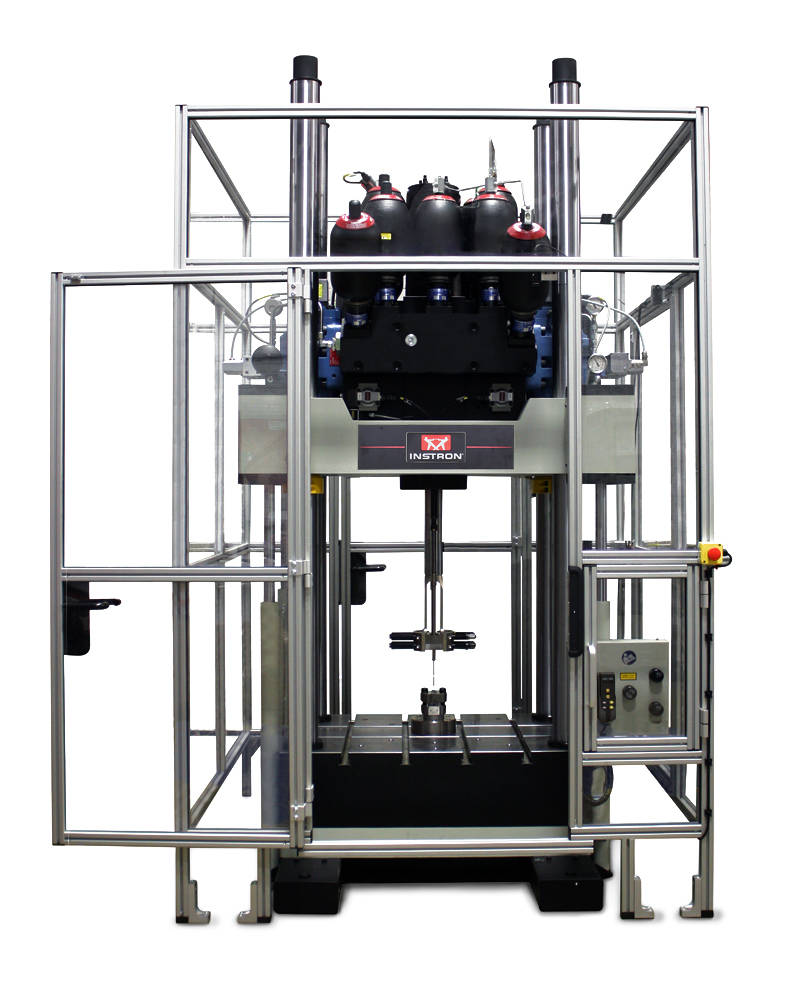

Features

The Instron VHS can characterize dynamic properties of strain rate dependent materials across a wide range of velocities, investigating material failure under high strain rate impact and identifying the most optimal design for weight.Static Load Capacity: 35 kN to 160 kN.

Dynamic Load Capacity: 50 kN to 100 kN.

Operates at 280 bar resulting in higher acceleration

Capable of velocities up to 25 m/s

Electronically interlocked protective enclosure

High-stiffness load frames

Patented FastJaw gripping solution

VHS8800MT controller and high-speed data acquisition package with 8 channels and very high sample rate

High Strain Rate Materials Characterization for Crash Structure Modeling

High-Strain Rate VHS systems characterize strain rate dependent materials such as automotive crash structures at test speeds of up to 25m/s.

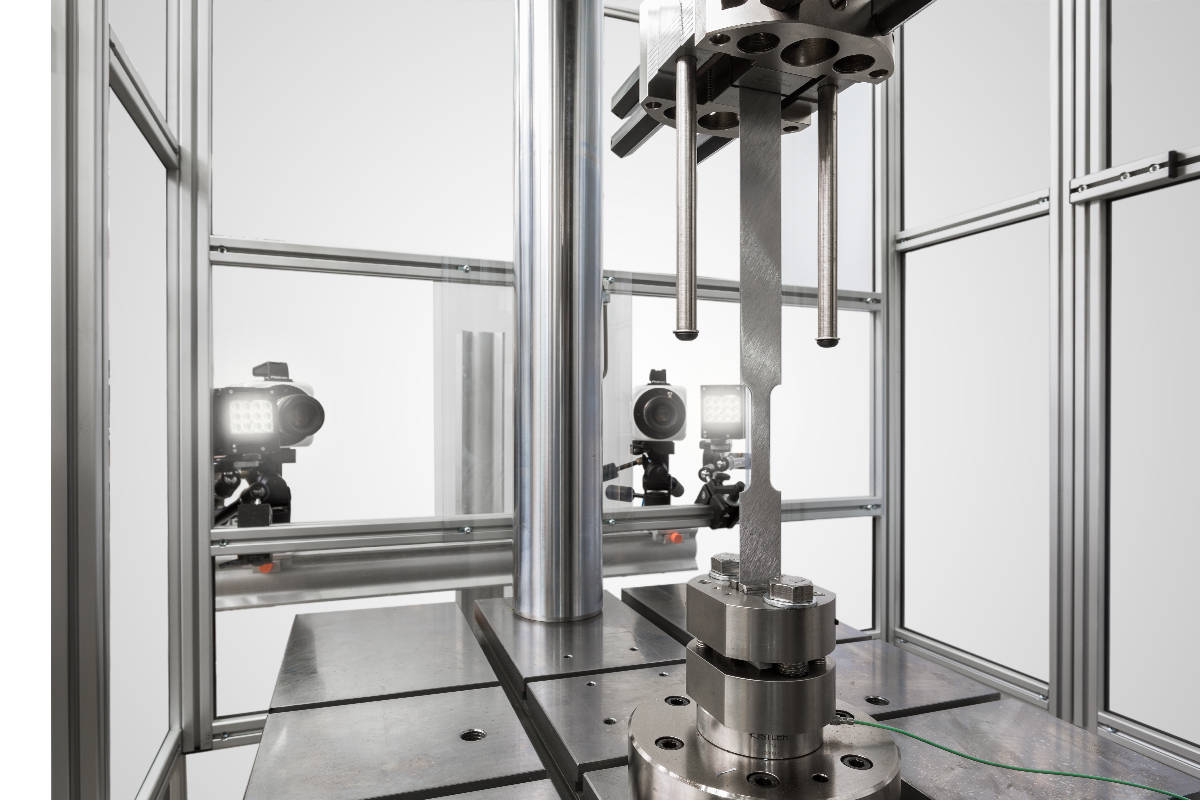

Instron VHS testing systems are supplied with a VHS8800MT controller package and Instron HighRate software to provide high quality control, data acquisition and calibration features. The controller is suitable for a wide range of applications and complex velocity profiles, and the latest Bluehill® VHS Analysis software provides statistical analysis and powerful tools for quick post-processing modelling. Optional Digital Image Correlation (DIC) systems allow for non-contacting strain measurement and can be fully integrated with the VHS system, offering complete testing capability.

It also supports use of virtual strain data exported by DIC analyses, and even comparable raw data from other test machines for lower strain rates.

Bring modern, user-friendly tools to working with high rate test data and improve repeatability and traceability of your results.

LEARN MORE

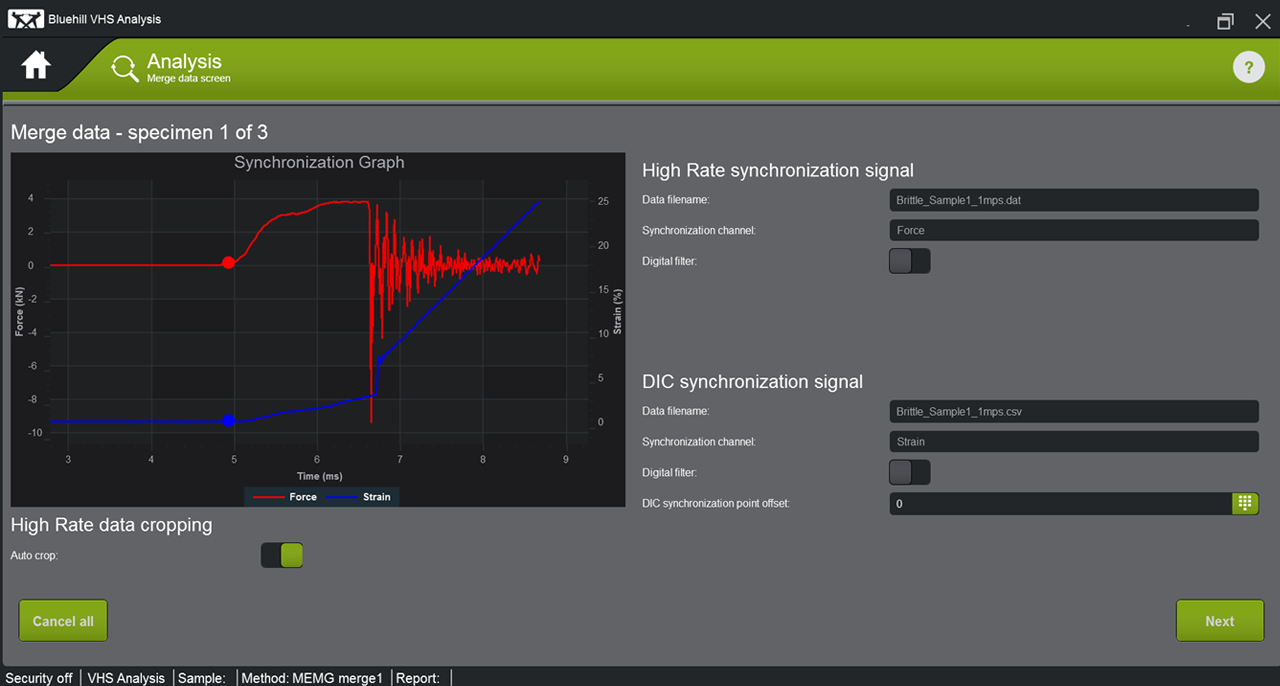

Bluehill VHS Analysis

Bluehill VHS Analysis is the most modern package on the market for analysis of high rate materials test data. Designed to integrate with data generated by Instron VHS machines, this software provides a complete solution covering needs ranging from routine batch testing, to unique specimen analysis, or initial test development.It also supports use of virtual strain data exported by DIC analyses, and even comparable raw data from other test machines for lower strain rates.

Bring modern, user-friendly tools to working with high rate test data and improve repeatability and traceability of your results.

- Import raw data and perform analysis

- Generate standard materials characterization results

- Handle batches of specimens

- Report and export results data

LEARN MORE

Smart data import and synchronization

- Combine force and specimen data from Instron VHS with external strain data from DIC

- Automatic synchronization using advanced algorithm to align and merge data

- DIC data is automatically up-sampled so that the faster data stream is not lost

- Automatically crop unused run-in and run-out data

Create repeatable analysis methods

- Create methods for different batch tasks or start afresh with a unique test

- Apply consistent data processing between tests

- Extract material characteristics such as modulus and yield strength according to international standards

- Allow expert users to optimize settings per specimen

- Review batches and create new reports

- Protect method integrity by enabling user security features

More user-friendly tools

The Instron VHS can characterize dynamic properties of strain rate dependent materials across a wide range of velocities, investigating material failure under high strain rate impact and identifying the most optimal design for weight.

Data preparation

- Automatically identify the test region

- Apply clear and easily comparable filters to exclude noise

- Create average curves from groups of specimens

Calculations

- Built-in calculations for key analysis needs

- Quick and simple to set up

- Powerful user-defined calculations for customized measurements

Outputs

- Configure results tables for batch tests

- Create report templates

- Export processed results for external data management