Shoe and shoe material manufacturers alike must be able to prove that their products will withstand a substantial amount of wear and tear before releasing them to market. Useful in this analysis is the ability to simulate the impact of a runner on the sole of a shoe. During a typical gait cycle, these impacts can be higher than 3kN for an adult runner. In addition to controlling the load with which an impact is generated, researchers may also wish to control the energy which is generated as a result of the impact. A testing machine, which can successfully cater to these requirements, must be able to create and maintain a repeatable impact of a certain energy over a prolonged number of cycles.

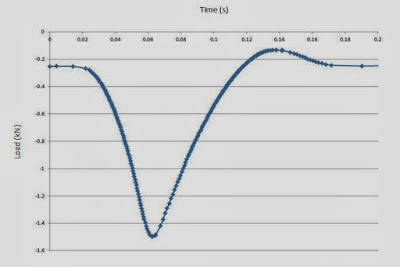

Custom waveforms were created to replicate the impact of actual gait cycles. WaveMatrix™ software allows users to create and import their own custom waveform in the form of a CSV file, achievable in Microsoft® Excel. Through this custom waveform tab, customers also have the ability to specify a very precise impact duration. The up-to-5kHz acquisition rate of the 8800 Controller enables the waveform to be precisely controlled in the magnitude of milliseconds. As materials testing machines usually have two main controllable transducers, Instron established a method for achieving the given energy requirement for each impulse. The Advanced Amplitude Control is a feature of WaveMatrix that is key to conducting energy-controlled impulses, using a combination of controller gains to make sure that the energy requirement is met for each iteration of the impulse. The combination of this feature, in conjunction with the Calculations Module, allows the ElectroPuls™ to test footwear based on constant load, energy or any other requirement included in the calculations portion of WaveMatrix.