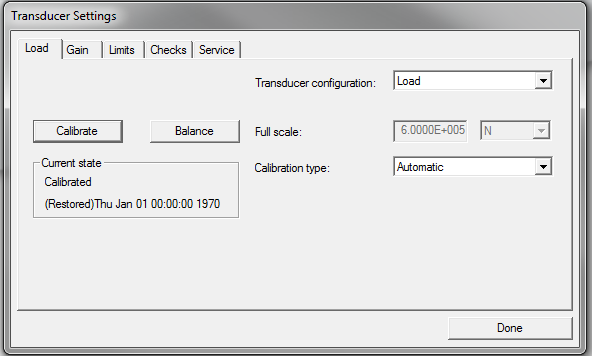

Prior to testing a batch of specimens, you should ensure that your load cell is properly calibrated and balanced – both actions are done right in the software. In Bluehill® 3, this can be done from the console at the top of the screen. Simply click on the load cell icon, and then click "Calibrate". We refer to this as a software calibration (or “soft-cal”), which also balances the load cell.

- We recommend that the machine and load cell be switched on for about 15 minutes prior to performing a soft calibration. This allows the device to warm up, reducing the chances of drift.

- Make sure you are not gripping a specimen when you perform a soft-calibration. It is okay to leave the upper grip or fixture attached to the load cell during the calibration – but it is also okay to leave it off. Just remember to perform an additional balance once the grip or fixture is added to the load cell.

- Again, do not balance the load cell once the specimen is loaded into a grip or fixture. The force you see is real mass of the specimen, or force on the load cell. Balancing out this load would be like balancing a scale after you have put one foot on it (Note: this means the load cell should not be auto-balanced after preload).

- Though many systems will automatically recognize a load cell and restore its previous calibration every time it is plugged into the system, it is good practice to perform this soft-cal regularly, especially if swapping load cells. What does regularly mean for your system? Contact us, and we’ll help you figure it out.

Remember that a soft-calibration is not a replacement for on-site verifications by Instron Professional Services on a regular basis. For most laboratories, this means at least once a year, but your industry standards or internal protocols may differ.