What Value Does ISO 9001 Add?

Continual Improvement

There is an entire section of the ISO 9001 standard dedicated to improvements (8.5 Improvement) and a specific requirement (8.5.1 Continual Improvement) for an organization to “continually improve the effectiveness of the quality management system …” Instron has always had a strong focus on continual improvement, but this was amplified when Instron was acquired by ITW in 2005. ITW has put continuous improvement at the forefront and sets annual goals to measure this achievement.

In addition to these continual improvement projects, we also have a defined process for corrective and preventive action (8.5.2 and 8.5.3 respectively). What this means is that when we identify a non-conformity we have a process that not only reviews the issue at hand but seeks to prevent that issue from recurrence.

In addition to these continual improvement projects, we also have a defined process for corrective and preventive action (8.5.2 and 8.5.3 respectively). What this means is that when we identify a non-conformity we have a process that not only reviews the issue at hand but seeks to prevent that issue from recurrence.

Customer Satisfaction

We are proud to boast a customer satisfaction rating of nearly 90% and find ourselves in good company with the likes of Mercedes Benz, Lexus and Toyota. To assess customer satisfaction (8.2.1 Customer Satisfaction), Instron uses third-party providers to survey how we did throughout the customer experience. In cases where we find our customers less than satisfied, we have a designated process to follow up with the customer, understand the issue, and solve it. This again points to our corrective and preventive action policy (8.5.2 and 8.5.3).

We truly value customer input and are constantly asking what we can do to better serve our customers. When I am a consumer, I’m always happy to know that a company is interested in my assessment of their product. With these surveys, it’s clear to see Instron has the same mindset.

We truly value customer input and are constantly asking what we can do to better serve our customers. When I am a consumer, I’m always happy to know that a company is interested in my assessment of their product. With these surveys, it’s clear to see Instron has the same mindset.

Freedom from Defect

We touch on this quality objective in several points in our processes. We chase freedom from defect, starting at the earliest points in our design process. Previous failure information is an input into new product development. As we work with our suppliers to procure goods, we evaluate our suppliers (7.4 Purchasing) prior to doing business and hold them accountable to our quality standards. We meet on a quarterly basis with key suppliers to review their performance and make supply chain decisions based on their performance. If we can’t receive a quality product when needed, we realize that affects our ability to get you a quality product on time. We also investigate returns of discrepant material from customer sites (8.2.4 Monitoring and Measurement of Product). With our intense focus on reduction and elimination of defects, you can feel more confident as a customer that our products and our processes will meet your demands.

Reliability

Instron has a rigorous design and development process (7.3 Design and Development), which is managed by several stage gates. We have defined requirements for each gate that shall be completed, and criteria that must be met prior to release of the product. This means that you have a reduced risk in doing business with us because our engineering designs are thoughtful and thorough. The designs have been reviewed, tested, tweaked and tested again before being released.

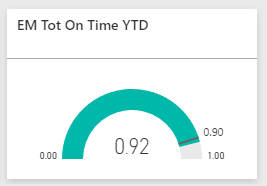

We are also reliable in terms of our time commitments to you. Instron measures our on-time shipment performance (8.2.3 Monitoring and Measurement of Processes). Currently, we are at 92% on time for the year.

We are also reliable in terms of our time commitments to you. Instron measures our on-time shipment performance (8.2.3 Monitoring and Measurement of Processes). Currently, we are at 92% on time for the year.

Safety

Safety is a key word at Instron, and you can find our focus on it throughout the organization. Foremost, we can confidently identify our designs are safe because prior to release of the product (7.3.4 Design and Development Review), a safety officer and the design engineer conduct a comprehensive review and risk assessment. Operator safety is a key consideration in all of our designs. If the design does not meet the requirements of the safety audit, that product will not ship until the appropriate changes have been made to the design.

While manufacturing our product, safety is actively practiced to keep the shop floor safe (6.4 Work Environment). We have implemented a 5S+S program where workstations are reviewed for cleanliness and safety.

Our service engineers in the field have undergone training (6.2.2 Training) on best practices for a safe working environment. Moreover, as part of new customer installations, these service engineers can provide instruction on safe operation of your new Instron.

To garner the culture of safety throughout the company, our Safety Committee meets monthly with employees from all departments in the organization, and our Hazard Hunt program rewards employees for identifying potential safety hazards. Just last fall, we carried out a Safety Risk Assessment Tour at our Worldwide Headquarters and had over 90% employee participation at that facility.

While manufacturing our product, safety is actively practiced to keep the shop floor safe (6.4 Work Environment). We have implemented a 5S+S program where workstations are reviewed for cleanliness and safety.

Our service engineers in the field have undergone training (6.2.2 Training) on best practices for a safe working environment. Moreover, as part of new customer installations, these service engineers can provide instruction on safe operation of your new Instron.

To garner the culture of safety throughout the company, our Safety Committee meets monthly with employees from all departments in the organization, and our Hazard Hunt program rewards employees for identifying potential safety hazards. Just last fall, we carried out a Safety Risk Assessment Tour at our Worldwide Headquarters and had over 90% employee participation at that facility.

Suitability

Instron continuously serves customers in a wide variety of industries. If you don’t think your industry applies, I’d be willing to bet we could get to a relationship well before we’ve saturated all six degrees of separation. For this reason, our products are suited for specific use (7.2 Customer-related Process). As part of the order process, upon receipt of an order, we organize a suitability review of the content of that customer request. You can rest easy knowing that we’ve captured your testing needs and verified that you will have what you need to carry out tests upon arrival of the equipment.

Originally posted on August 31, 2016 , Updated On June 19, 2024