Thermal degradation of polymers corresponds to deterioration at a molecular level, for example as a result of (over-)heating. Polymer degradation is normally undesirable since related to the loss of properties in the finished product. Some of the recently developed thermoplastics, used as neat or reinforced high-performance materials, are suitable for high-temperature applications, but they are also exposed to high temperatures during compounding and molding processes. Therefore, they're highly sensitive to processing conditions and may undergo thermal degradation before becoming the finished product. This applies for example to LCP (liquid-crystal polymers). One of the key parameters when processing this type of materials is their degradation time and temperature.

How long can a polymer withstand given processing conditions in terms of working temperature and shear rate? To answer this question, a standard rheological test is not enough. With Instron-CEAST capillary rheometers and related Visual RHEO software, a further analysis is possible by performing a Thermal Degradation test. Setting a working temperature and one shear rate applied over a range of time, viscosity is measured as a function of time. Thanks to this type of test, it's possible to quantify the change in viscosity (typically a decrease) of the material during processing applications.

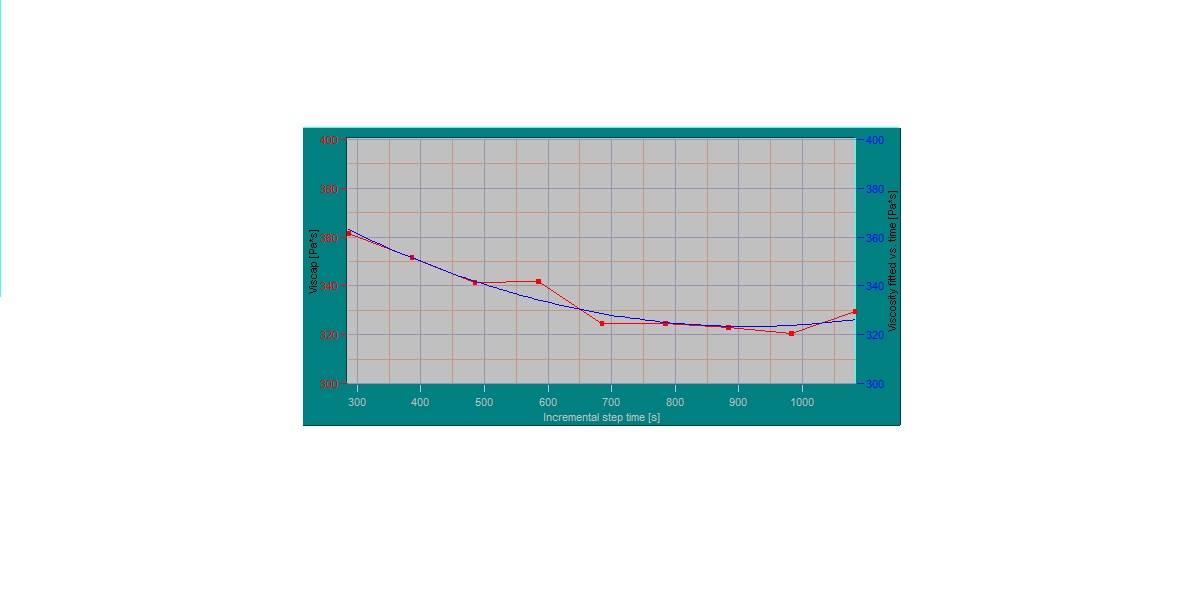

A raw material producer interested in new R&D and Quality Control procedures asked us to test their LCP samples at a high processing temperature. The samples were previously dried in a vacuum oven, then tested at 350°C (662°F) by using a CEAST SR20 capillary rheometer. The thermal degradation test was performed for 15 minutes at a fixed shear rate. Viscosity obtained from experimental data was plotted against time. Viscosity values at selected time intervals were determined using the fitted curve of viscosity vs time. Such values can be used as a reference value to grade different samples. For the specific sample tested in our lab, a loss in viscosity of about 10% was observed, comparing data at 5 and at 10 minutes after loading the sample in the heated barrel of the rheometer.