Rheology analyzes the flow properties of fluids and is key to understand their behavior under industrial processing conditions. Low viscosity fluids are usually tested with rotational rheometers, but this is not enough when high-shear processing conditions need to be simulated. So depending on the application, this kind of fluids (such as paints, glues, adhesives, etc…) should preferably be tested by means of a capillary rheometer.

We were asked to test glue and paint samples consisting of water based polymer dispersion, in order to investigate suitability of a spraying process (very high shear). We used a capillary rheometer Instron CEAST SR20, managed through the dedicated VisualRheo software. The machine (15 mm barrel diameter) was equipped with a 20-kN load cell. Two low-range pressure transducers were used (3.5 and 20 MPa) to cover the whole testing range. Thanks to the reduced diameter of the capillary (0.25 mm), having a length of 1.25 mm, the shear rate range could reach 2 million 1/s. In order to avoid leakage, we used a special piston with PTFE sealing rings.

Rheological tests (ISO 11443) were performed at room temperature by applying constant shear rate steps in a range from 3’000 to 2’000’000 1/s, and measuring pressure at equilibrium. Tests were repeated three times on each sample in order to evaluate the repeatability of results.

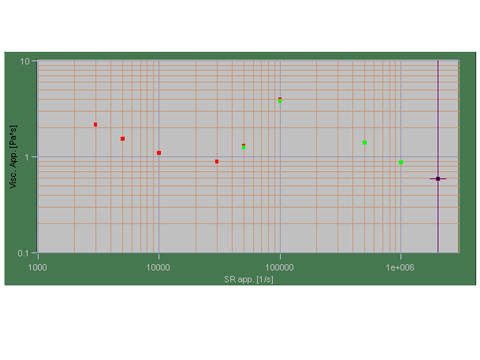

The results were presented as rheological curves (see picture): viscosity (Pa*s) vs shear rate (1/s). The qualitative behavior was similar for glue and paint (both engineered for spraying application), with very low viscosity in a range from 0.04 to 4 Pa*s.

The rheological behavior of these fluids is very particular, since the viscosity plot is not monotonic as for standard polymer melts – where typically viscosity decreases when shear is increased. Here viscosity decreases or increases depending on the shear range, with a maximum at intermediate shear conditions. Results showed a very good repeatability since all curves of the same sample were perfectly overlapping.