Did you know that the liner inside a bottle cap is a highly engineered part? Selecting a suitable cap liner is a critical task in order to ensure a tight seal upon closing the bottle cap. When the bottles contain food items, water, soft drinks, medicines and products that are directly associated with consumer safety, the material of the seal is of utmost importance. The liner materials are chosen based on various requirements like leakage prevention, creating a moisture barrier, chemical resistance, and shelf life. A wide variety of polymers (Teflon, silicone, polyolefins), paper-backed foams, aluminum foils, are used for manufacturing cap liners.

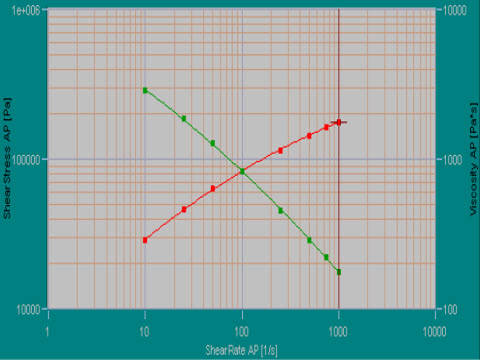

We were approached by a cap liner manufacturer who was keen on understanding the flow behavior of plastic materials used for liners, in order to mold quality parts fitting tightly inside the bottle cap and providing a good seal. We used our CEAST SR20 Capillary Rheometer to test a Polypropylene (PP) compound which was melted at 230°C with a preheating time of 900 seconds and a compacting force of 5000 N before extrusion through a 20 mm capillary die. This PP compound was subjected to incremental shear rates in a range of 10 s-1 to 1000 s-1 as a result of which decreasing viscosity values of 2875 Pa•s (at 10 s-1) to 176 Pa•s (at 1000 s-1) were observed.

We noticed that this material required a longer preheating time, and a higher compacting force for melting it homogeneously without air bubbles. In comparison, a neat PP grade will melt homogeneously between 200 and 250°C after preheating for about 300 sec followed by compacting at a controlled force of 500 N. Overall, we were able to obtain repeatable results from testing this material. The shear rate vs. viscosity plot (green line) on the right shows that the material is highly shear sensitive.