EN 14509 specifies requirements for factory made, self-supporting, double skin metal faced insulating sandwich panels, which are intended for discontinuous laying in roofs and roof cladding, external walls, and wall cladding. The insulating core materials covered are rigid polyurethane, expanded polystyrene, extruded polystyrene foam, phenolic foam, cellular glass, and mineral wool.

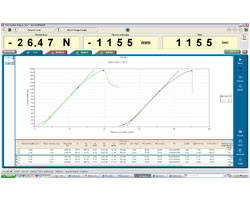

The standard specifies a number of requirements relating to the mechanical resistance of the panel, including the determination and specification of the Shear Strength and Shear Modulus of the core of the panel. This is determined using a four-point bend test where the ultimate load carried by the specimen failing in shear must be measured and where the shear modulus is calculated from the load deflection curve.

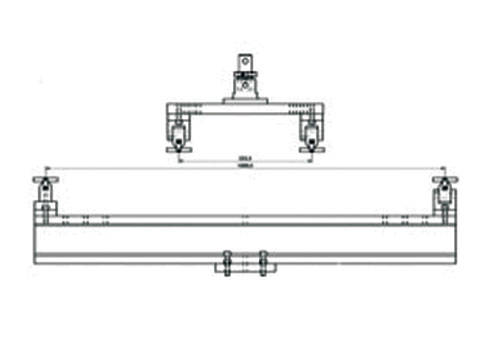

It is important that the flexural fixture is designed to minimize play or backlash, and that the loading plates that contact the sample are of sufficient width to prevent damage to the surface of the core. Maximum test loads depend on the core thickness and material, but are typically below 50 kN. For this test, we suggest using a 6800 Series Universal Testing Machine combined with Bluehill® Software, which can automatically calculate the values of Shear Strength and Shear Modulus.