Pill crush testing is performed in order to understand the compressive properties of pills. This is to ensure that a pill is able to withstand a variety of forces that may occur during manufacturing, packaging, shipping, and handling. A typical test requires a pill to be either compressed to failure or compressed to a certain force and checked for puncture. Although the test itself is relatively straightforward, having the appropriately sized compression platen or probe is critical to ensure the pill does not slip out from under load, and that the force is properly distributed over the surface area of the pill.

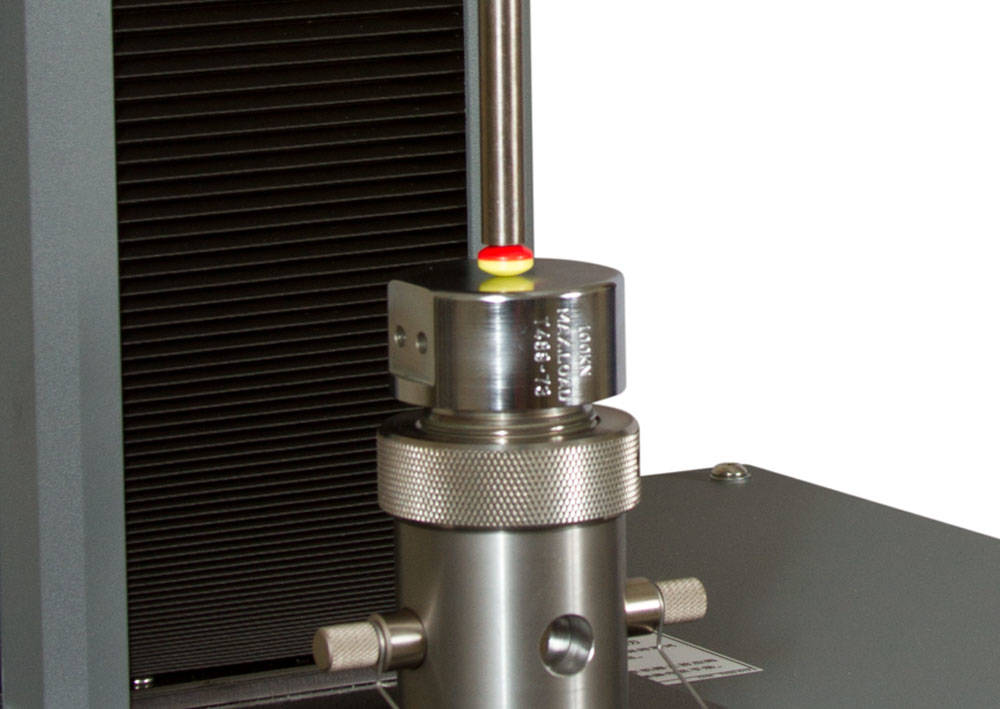

In order to simulate pill crush conditions that could occur during the production, shipping, and handling of a pill, we recommend carrying out pill tests at a range of speeds. Using choice inputs and linked values in Bluehill® Universal software, it’s possible for a user to select a simulation condition (i.e. packaging versus handling) using a simple drop-down menu in the software that will change the test speed behind the scenes. In addition to test speed, we recommend using at least a 2 inch compression platen on the base of the system, and a smaller probe on top to closely match the pill's diameter.