CT6 COBOT TEST SYSTEM

Automated Collaborative Robot for Testing Biomedical Devices and Components

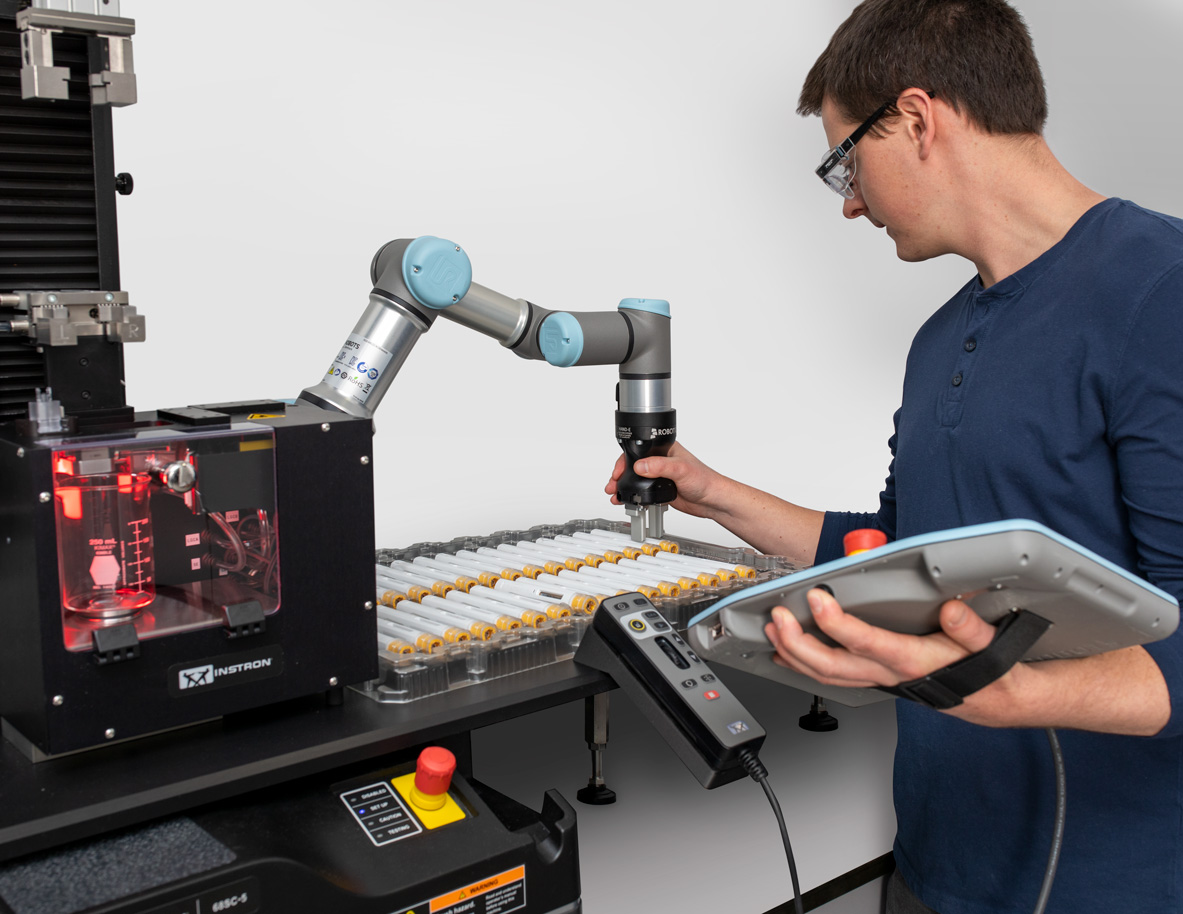

The CT6 cobot testing system introduces the benefits of automation to the testing of biomedical devices and components. This system pairs a collaborative robot with a 5900 or 6800 Series universal testing system to increase the efficiency of small to mid-sized testing labs that require a high degree of flexibility in their testing systems. The CT6 is designed to handle a wide range of medical components, including drug delivery, sample collection, and wound closure products.

Request a Quote or Demo

Instron’s CT6 offers the benefits of automation to labs with shifting test requirements and specimen geometries. The CT6 integrates an easy-to-program cobot with a universal testing machine and Bluehill® Universal software to better enable QC and DV labs to meet their growing testing demand while improving the overall reliability of the data. Utilizing the CT6 avoids the hassles associated with using third party integrators by leveraging Instron's automation capabilities and application expertise.

The CT6 is an ideal automation solution for small to mid-sized labs where engineers often spend valuable time operating testing systems. The CT6 acts independently to load specimens, run tests, and unload specimens, allowing skilled operators to dedicate more time to value-added activities.

The CT6 is designed to be quickly and easily programmed with little to no help from Instron. This means that testing new devices or specimen sizes can be automated in-house with minimum time required for the initial setup.

The CT6 mitigates risk by ensuring that the operator is outside of the test space at all times when the frame is in motion. It also reduces operator interaction with hazardous specimens such as sharps and avoids the strains associated with repetitive loading and unloading of the system.

The use of the CT6 eliminates any operator introduced errors related to specimen alignment or data collection.

The CT6 is designed to be paired with existing or purpose-built fixturing to perform tests on a broad range of products and components. Our automation team can support the design and development of all automation-ready fixtures and specimen racking. Alternatively, the CT6 can serve as an add-on to your equipment, leaving the implementation to internal design teams. Here are some of the most common applications where the CT6 is optimal for introducing simple pick-and-pull automation to your lab.

Manufacturers of autoinjectors and other needle-based injection systems are ramping up production to meet the rising global demand for safe and convenient forms of drug delivery. Bringing these devices from development to production is a long process with strict requirements for both functional and usability testing of the devices through each stage of product development. The CT6 is ideal for testing various design iterations of a product with minimal changeover time, reducing the burden on highly technical design engineers to stand in front of a system. With a cobot solution, the devices can be placed in the production tray directly on the test system and left, while the machine runs the necessary tests. This ultimately allows the technician to accomplish other value-added tasks.

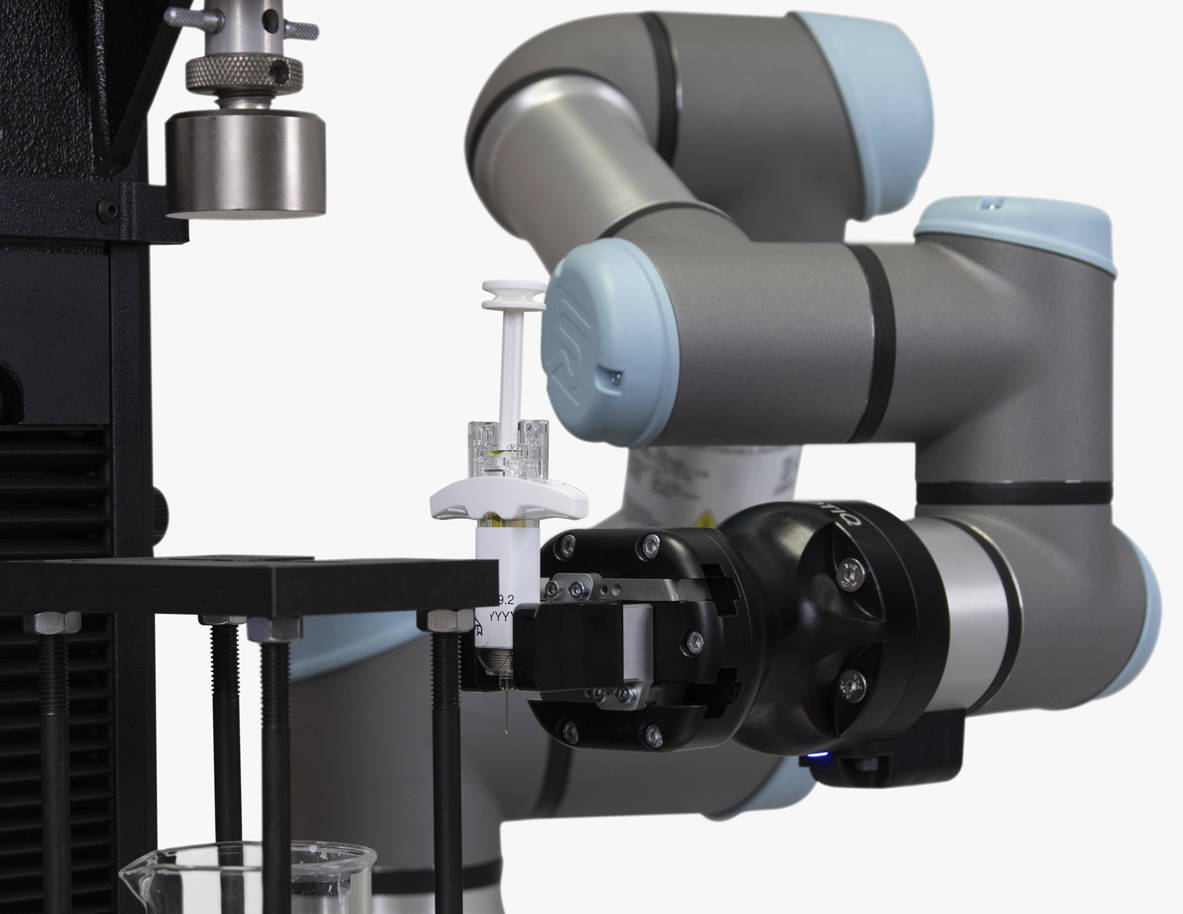

Break loose and glide force testing constitutes the bulk of syringe testing and is used to determine the real-world forces required to operate the syringe. Pre-filled syringes are combination devices requiring device verification testing before an NDA can be submitted. Cobots can be placed separately or in-lined to improve throughput and efficiency in both of these applications. Fully integrated manufacturing systems can even use measured break/loose glide force data to modify production settings in real time to correct for any out-of-tolerance values. The CT6 is compact enough to be placed directly in existing testing labs on tabletop systems to perform the required device evaluation, allowing engineers to focus their effort on data analysis and consolidation.

Prefilled syringes have a wide range of closure systems including rigid need shield and screw on tip caps. ISO 11040-4 is the global standard outlining the test procedures necessary to evaluate the performance of these closures. Annex G.5 specifically assesses the removal torque of rigid tip caps used in conjunction with female luer lock connections. When used in conjunction with a torsion-enabled universal testing system, a cobot can be extremely beneficial for lab productivity - essentially functioning as a pick and place operation to reduce operator influence. The repeatability of automated specimen insertion is also ideal for improving device alignment, a significant contributor to data spread. Since prefilled syringes can come in a range of capacities, the sample racking can be customized to accommodate all potential device geometry, and the seamless integration with Bluehill Universal means test methods for new devices can be created quickly.

| SPECIFICATIONS | |

|---|---|

| Payload | 3 kg | 6.6 lbs |

| Reach | 500 mm | 19.7 in |

| Weight | 11 kg | 24.3 lbs |

| Speed (TCP) | 1 mm/sec | 39.4 in/sec |

| Repeatability | ±0.03 mm |

| Power Consumption | 300 W |

| Operating Temperature | 0-50°C | 32-122°F |

| Humidity | 90% RH |