There are two methods to calculate R-value, a manual version and an automatic version. We can assume that the volume of the specimen during the test remains constant to make the calculations easier (see below for details). The manual version of calculating R-value requires that the user measure the initial and final width and length of the specimen using calipers. The automatic method requires the user to measure the axial strain (as opposed to the strain along the thickness of the specimen) and transverse strain to calculate R-value.

The best range over which to calculate R-value is after yield point elongation and before ultimate tensile strength. The benefit of using the automatic method of measuring R-value is that the specimen can be pulled until failure, thus allowing the user to calculate properties such as ultimate tensile strength or strain at break. However, in the manual method, you are to pull the specimen beyond yield-point elongation, but the strain should not exceed the strain at ultimate tensile strength. Once you pull the specimen to this point, you are to unload the specimen to take the final measurements with your caliper.

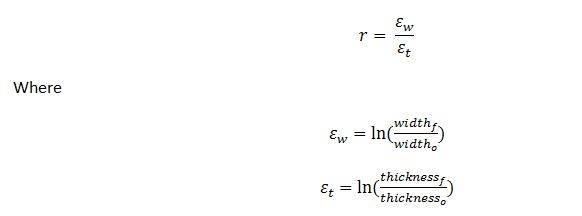

The equation to calculate R-value is shown below:

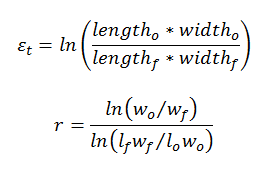

Since it is difficult to measure the thickness of the material as it is plastically deforming, we can assume that the volume of the specimen remains constant and thus:

To learn even more about R-value, check out ASTM E517 or ISO 10113.