Fulfilling the requirements of industry standards and being competitive in the market are keys to success in the automotive sector. In the automotive industry, design and performance are equally important. For example, the airbag cover and the exterior trim should be functioning at the highest quality, while at the same time, be aesthetically pleasing. Many cars have leather interiors: leather gives a delicate touch of luxury and elegance to a car.

A manufacturer of car interiors contacted Instron® to check the quality of leather used to cover airbags, including its behavior after sunlight and climate changes. Estimating the performance of a material covering airbags involves many factors around costs and benefits.

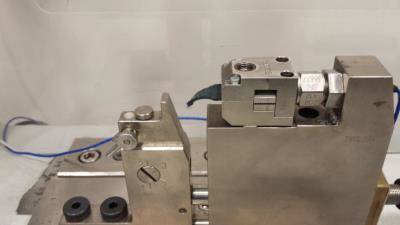

Instron advised to measure the tensile strength of leather during an impact according to ISO 8256 Method A. With a CEAST 9050 Impact Pendulum, the test is simple and the set up is quick: the specimen (horizontally-oriented) is supported and clamped through a special vice. The free end of the specimen is clamped through a crosshead that will be impacted by the hammer. VisualIMPACT Software manages and analyzes the test results.