Instron offers a variety of automation solutions to improve your testing, from simple two-axis systems to six-axis robots and cobots. Here we look at the key factors to consider when addressing the specific challenges posed by biomedical device testing.

What is testing automation?

Testing automation stems from Industry 4.0 technology, specifically robots and cobots (collaborative robots). An automated mechanical testing system replaces some or all of the functions of a human operator, such as specimen measurement, loading, testing, and disposal. Each specimen is logged with a unique identifier for traceability throughout the testing process that allows any information generated during testing to be accessible later.

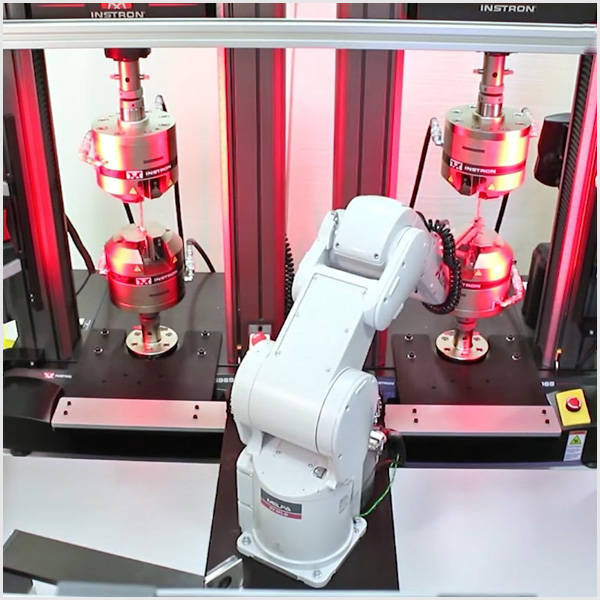

Automation systems can extend from simple two-axis stages mounted to single-column machines to more complex six-axis robots designed to maximize throughput without human intervention.

Choosing the right level of automation

The primary factors to consider when deciding on the level of automation include:

- How much variation there is in the materials and products tested;

- How much human intervention is required in terms of loading samples or interaction with the system;

- How much space is available in the laboratory; and

- Budget constraints and expectations in terms of ROI.

Instron has a broad range of automated systems to meet different lab needs.

AT2 is a simple two-axis semi-automated system that integrates with a universal testing machine for compression, tensile, and flexural testing. The AT2 automates a substantial portion of the testing process and can be fitted with custom fixturing to accommodate a variety of specimen geometries.

AT3 is an adaptable three-axis automated testing system for testing materials like rigid plastics, elastomers, rubber, thin film, foam, medical gloves, and metals. The integrated barcode reader allows the system to store all the relevant test information against the specimen barcode supplied by the operator.

AT6 is an industrial six-axis robot for use in high-volume laboratories. The AT6 has a capacity ranging from 200 to 1,000 specimens. The system has an integrated barcode reader and can include an optional automated specimen measurement station to further streamline the testing process. The AT6 robot performs tasks with high repeatability and includes hands-free specimen disposal, meaning the test is automated from start to finish.

CT6 is a cobot-based automated testing system. It operates at a slower speed, a smaller reach, and a lower payload than the AT6. However, the system is much easier to set up by operators without extensive programming experience. Cobots can operate without a physical guard in some instances, which makes the required footprint much smaller than robot systems.

The benefits of automated mechanical testing

Automated mechanical testing systems offer benefits for safety, quality, and efficiency.

- Safety is improved by reducing the interaction between operators and specimens, meaning lower exposure to hazardous substances or sharp and abrasive materials.

- Quality is improved by removing the variability that comes from human operators performing repetitive tasks. Automated systems perform tasks with precision and in an identical manner each time. They also follow the test method without any risk of deviation and can be updated with method changes as they are issued.

- Efficiency and throughput are improved in one of two ways. Some automated systems perform tests faster than manual systems. This means that the laboratory can accommodate more specimens without adding personnel. Even where the automated system does not produce faster results, the system still frees up operator time for more value-adding tasks.

Conclusion

Automation of mechanical testing replaces some or all of the functions performed by human operators. Solutions come in the form of two-axis semi-automated systems and extend up to six-axis robots and cobots. Each system offers unique features suitable for specific applications. While robots offer the highest throughput and complete automation from start to finish, cobots offer high flexibility and ease of programming.

The benefits of automation depend on the needs of your specific laboratory, including throughput requirements, bench space, and the types of testing being performed. A thorough analysis of your application needs will allow you to strategically select the automation solution that will best benefit your laboratory.

If you want to learn more on how to optimize repeatability, efficiency, and safety in your lab, download THE ULTIMATE GUIDE TO MECHANICAL TESTING AUTOMATION IN BIOMEDICAL APPLICATIONS.