The Overview

Branching off from an elite collaboration effort that involved materials used in thermoplastic composites, The ThermoPlastic Composites Research Center (TPRC) is a spin off from the University of Twente, one of the top universities in the Netherlands.

Envisioned as an open innovation R&D center, TPRC is an independent institute that brings together a cohesive group of international partners from various industries, like aerospace and automotive, to focus on ways to enable a wider use of thermoplastic composites materials.

The Challenge

Composite materials are a key component in the drive to reduce CO2 emissions; however traditional thermosetting composite materials are limited in their widespread application by high costs, the need for long processing times, and difficulty in recycling.

Thermoplastic composites offer the possibility of lower costs, much shorter processing times (comparable with injection molding) and recyclability. In addition, thermoplastic composites offer some significant performance advantages over thermosetting composites in some situations e.g. resistance to impact damage.

The characterization of process-related properties (often in polymer melt conditions) plays an important role in TPRC’s current research program. However, there are no standards that exist for the characterization of such properties, which is forcing TPRC to spend efforts in the development of new experimental techniques and procedures.

To be successful, it is necessary for TPRC to perform mechanical tests on materials, under both processing and end use conditions, to determine material parameters for use in process models, and to validate models and material performance.

Driven by the need to perform excellent research to develop new test methodologies specifically for thermoplastic composites, TPRC began to research equipment that matched the type of testing they were performing: state of the art.

“It was absolutely necessary for us to find the proper solution for our environment, in which the majority of research is non-standard,” said Wouter Grouve, Senior Research Associate at TPRC. “A solution that includes fixture alignment, which is essential in composites testing, as well as an easy-to-use and flexible user interface.”

Utilizing similar systems to what the university mainly uses was not an option for TPRC. They were concerned about the lack of flexibility due to their need to future-proof their lab.

The Solution

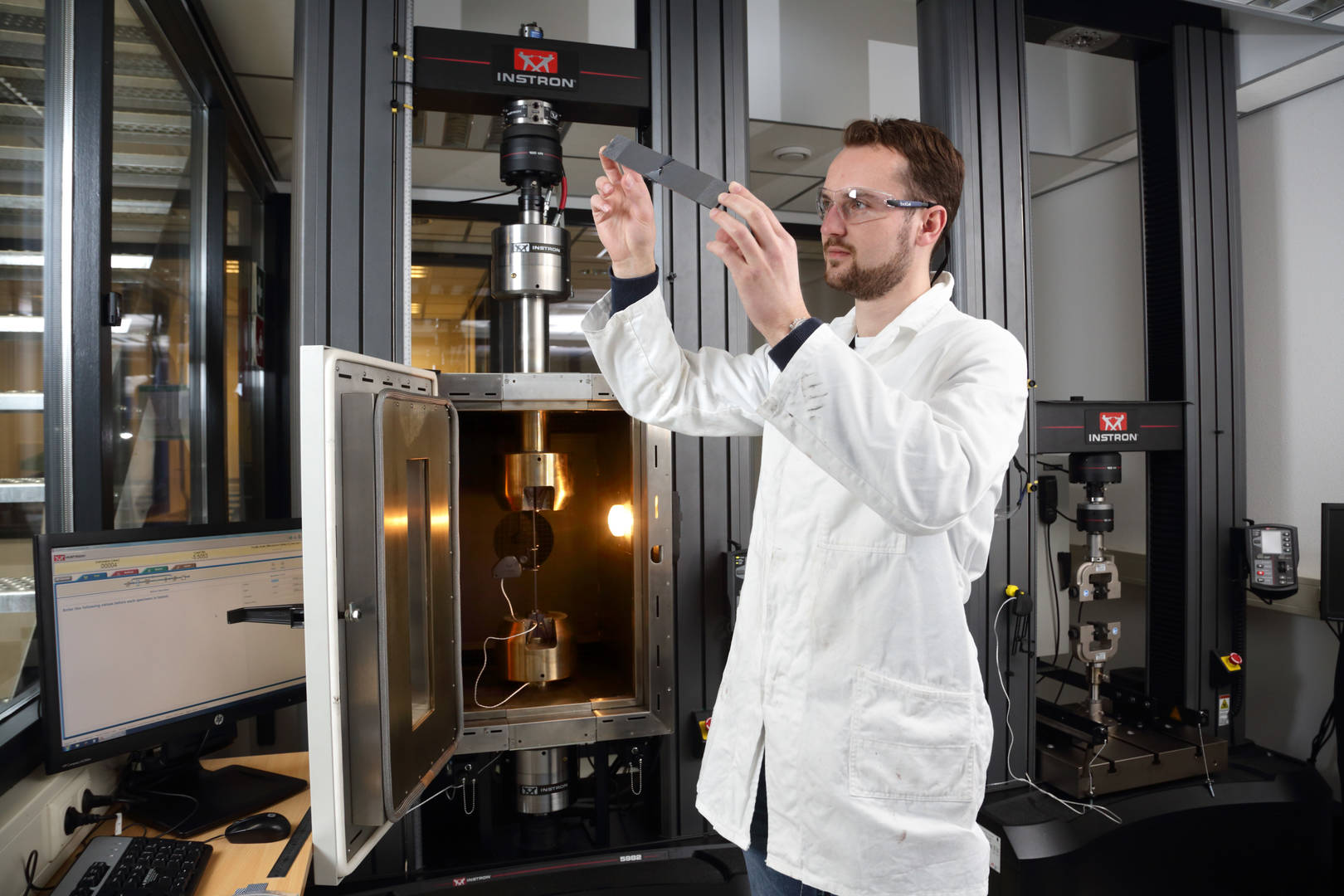

Looking for a testing machine that was capable of simulating and testing thermoplastic composite materials under process conditions (e.g. temperature), and was also flexible enough and offered modular load strings and accessories to allow for a wide range of standard and non-standard tests, led TPRC to investigate Instron electromechanical systems.

“Reliable test methods for static materials properties and stiffness, as well as tests to confirm the long-term durability in service, are essential to the successful introduction of thermoplastics,” said Grouve.

The implementation consisted of two 5982 floor model machines: one configured for laminate testing, offering very good alignment (exceeding Nadcap requirements) over a temperature range of -70 to +350° C, and a second system that performs tests at up to 600° C and can be fitted with different load strings and fixtures to cover a wide range of test types, mainly simulating processing conditions.

The Results

Since being installed in their lab a few years ago, Instron’s flexible and user-friendly 5982 testing systems have played a prominent role in TPRC’s material characterization program, as well as in the development of new test methodologies. The latter include the measurement of transverse compaction stiffness and shear response of woven fabric reinforced thermoplastic composites in melt conditions. These test methods provide material data essential for process simulations are gradually being accepted by the automotive and aerospace industries.