Peel Testing

An Introduction

A peel test is a basic form of mechanical testing that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite). Common results from a peel test are initial peak force, average force over the seal, and peel strength (average force per width of the specimen).

Peel testing is critical for evaluating the seal strength of various adhesive bonds. Some bonds, such as those that seal consumer packaging, are intended to be break at low forces, while others, such as those used in automotive applications, must withstand extreme conditions. When manufacturing adhesives and substrates, it is critical to have a thorough understanding of how your bonds will function in their end-use applications. Environmental conditions and specimen conditioning also play a significant factor, as temperature conditions over time can affect the strength of an adhesive bonds.

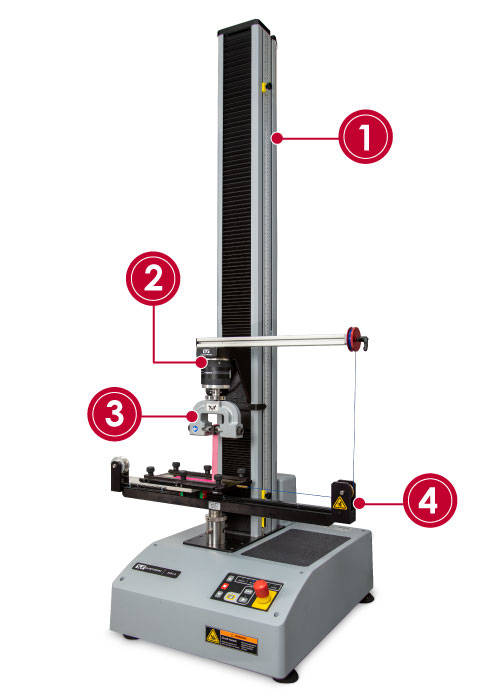

PEEL TESTING SYSTEM

Components and Parts

Peel tests are performed on universal testing machines that consists of a test frame that is equipped with a load cell, testing software, and application-specific grips and accessories. Many peel tests require the use of a specialized test fixture that maintains the specified peel angle throughout the test. 180° and T-peel testing require only tensile grips. The type of test and the material being tested will determine the type of accessories needed, and a single machine can be adapted to test any material within its force range simply by changing the fixturing.

| Peel Testing Machine | |

|---|---|

| 1) | Load Frame Testing machine load frames can come in single or dual column configurations depending on their force capacity. |

| 2) |

Load Cell The load cell is a transducer that measures the force applied to the test specimen. Instron load cells are accurate down to 1/1000 of load cell capacity. |

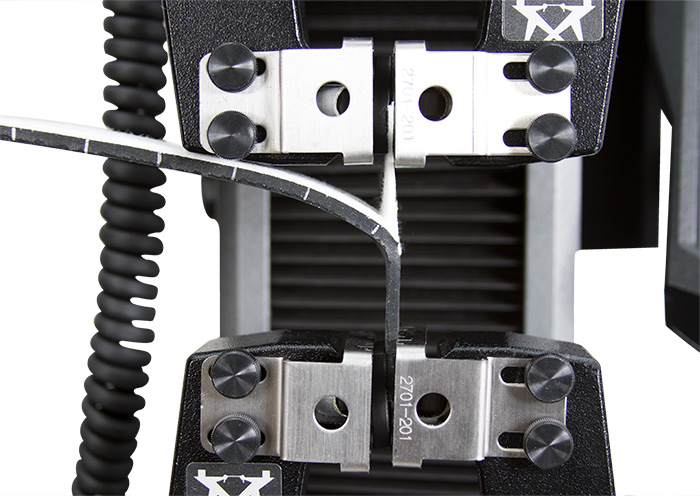

| 3) | Tensile Grip Most peel tests require at least one tensile grip, usually as the upper fixture. |

| 4) | Peel Testing Fixture Fixturing will depend on the specific type of peel test being performed, and can include specialized peel test fixtures or tensile grips. |

| Overview | |

| Catalog No. | 2820-035 |

| Associated Standards | ASTM B571, ASTM D2861 |

| Peel Angle | 90° |

| Maximum Load | 1 kN |

| Maximum Substrate Width | 127 mm |

| Maximum Substrate Length | 250 mm |

| Overview | |

| Catalog No. | 2820-036 |

| Associated Standards | ASTM B571, ASTM D429 (Method B), ASTM D2861, ASTM D3330 (Method F), ASTM D6252, ASTM D6862 |

| Peel Angles | 30°, 45°, 60°, 90°, 130°, 150° |

| Maximum Load | 1 kN |

| Maximum Substrate Width | 130 mm |

| Maximum Substrate Length | 250 mm |

TYPES OF PEEL TESTING

T-Peel Test

The T-peel test is performed on two flexible substrates that have been bonded together, such as the packaging of a medical or consumer device. The ends of the substrates are pulled apart using tensile grips. This setup forms a “T” shape.

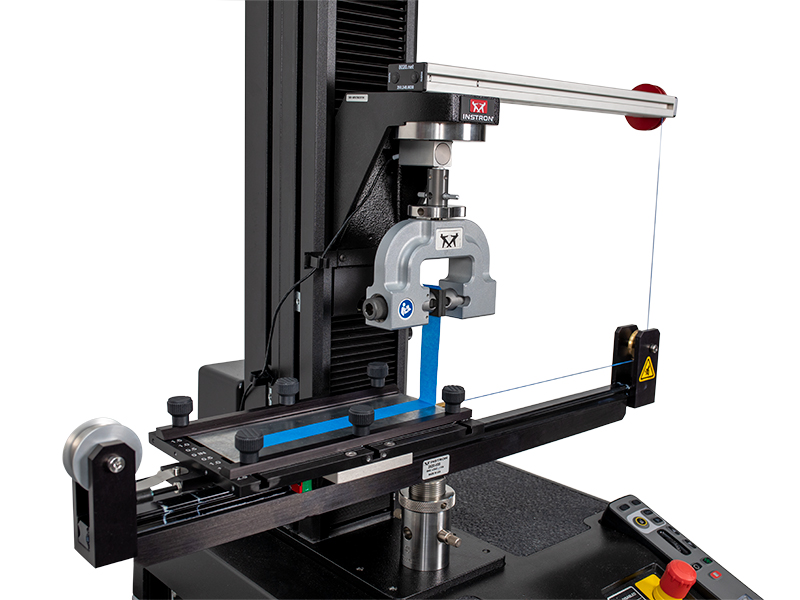

90° Peel Test

The 90° peel test is used to compare the bond strength of various adhesives between a flexible and rigid substrate. While a grip pulls the flexible substrate in the tensile direction, the rigid substrate is secured to a sled that moves laterally to maintain a constant 90° angle.

180° Peel Test

The 180° peel test attaches a specimen to a rigid substrate (plate), which is oriented vertically and held in place by the lower tensile grips. The end of the specimen is attached to the upper tensile grips. This setup allows tensile forces to be applied at a 180° angle.

PEEL TESTING STANDARDS

Common ASTM, ISO, and other Standards

ASTM F88 - Seal Strength of Flexible Barrier Material

ASTM F88 - Seal Strength of Flexible Barrier Material  ISO 29862/EN 1939 - Determination of Peel Adhesion Properties of Self-Adhesive Tapes

ISO 29862/EN 1939 - Determination of Peel Adhesion Properties of Self-Adhesive Tapes  ASTM D903 - Peel or Stripping Strength of Adhesive Bonds

ASTM D903 - Peel or Stripping Strength of Adhesive Bonds  FINAT Test Method No. 2 (FTM2) Peel Adhesion 90°

FINAT Test Method No. 2 (FTM2) Peel Adhesion 90°  ASTM D1876 Peel Resistance for Adhesives, T-Peel Test

ASTM D1876 Peel Resistance for Adhesives, T-Peel Test EN 12242 Peel Strength Touch and Close Fasteners (Hook and Loop)

EN 12242 Peel Strength Touch and Close Fasteners (Hook and Loop)  ISO 11339 T-Peel Test Flexible to Flexible Bonded Assemblies

ISO 11339 T-Peel Test Flexible to Flexible Bonded Assemblies