CONSTRUCTION AND BUILDING MATERIALS TESTING

Thanks to increased funding, critical infrastructure projects for roadways and bridges are expected to grow by $15.4 billion in 2023. Organizations hoping to secure new business from this funding must be able to maintain or increase throughput when testing construction materials to major ASTM and ISO standards that evaluate materials such as metals and concrete. Those who are prepared for new challenges can expect to see increased business opportunities. However, most DOT facilities are currently operating outdated testing equipment that is no longer operating optimally or even receiving support. Older test systems, even if well-maintained, are likely to experience extended periods of downtime should they require replacement parts, and may fail completely if those parts are no longer available. Organizations using inadequate equipment are at risk of causing project delays and losing business as a consequence.

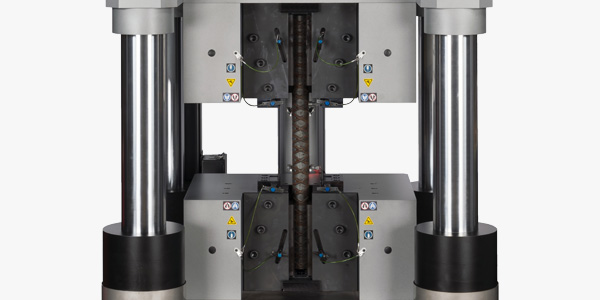

Steel reinforcing bar, or rebar, is critical to increasing the overall strength of the concrete that surrounds it. Global and regional level standards exist to help ensure that rebar produced throughout the world exhibits the same physical, chemical, and mechanical properties regardless of the source. Proper mechanical testing, including tensile, bend, compression, and fatigue, is often necessary for determining if the rebar meets its published specifications, ensuring the quality of the product. Common standards include ASTM E8M: 2013, ASTM A370, ASTM A615, ISO 6892-1:2009, ISO 15630-1, AC133, BS 4449, GB 1499, and JIS G3112.

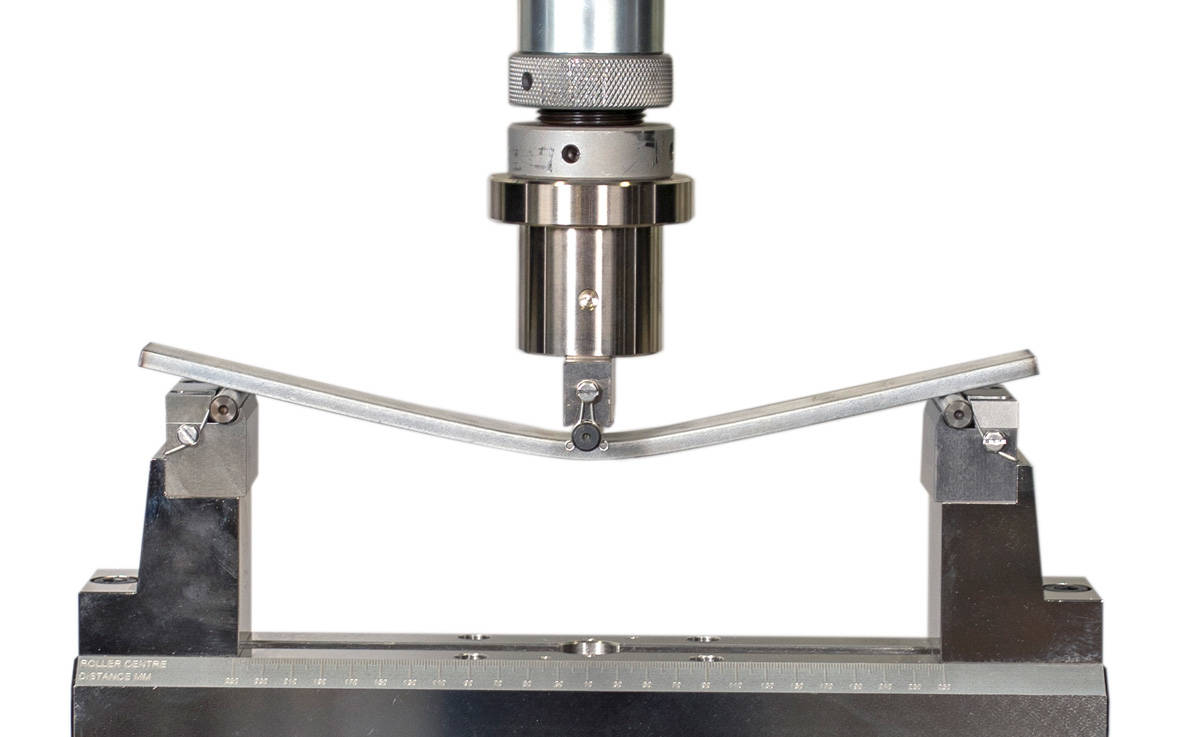

Performing Reinforcement Bar Bend Test to ASTM A370

Concrete is one of the world's oldest and most commonly used building materials. Most modern structures are built either partially or entirely of concrete, and it is also used extensively in the construction of roadways, bridges, and other types of infrastructure. Because of the obvious safety implications, accurate characterization of material properties is of the utmost importance when evaluating concrete. Standards such as ASTM C109, ASTM C39, and and ASTM C78 evaluate both compressive and flexural strength.

There are several major international standards for testing metals and metallic materials, and Instron systems have been designed with their requirements in mind. To simplify testing, Bluehill Universal software includes a metals application suite that contains test methods for ASTM E8, ISO 6892, ASTM A370, and other key standards. Instron's high force electromechanical systems are suitable for testing a wide range of metal specimen geometries in both ambient and non-ambient conditions.

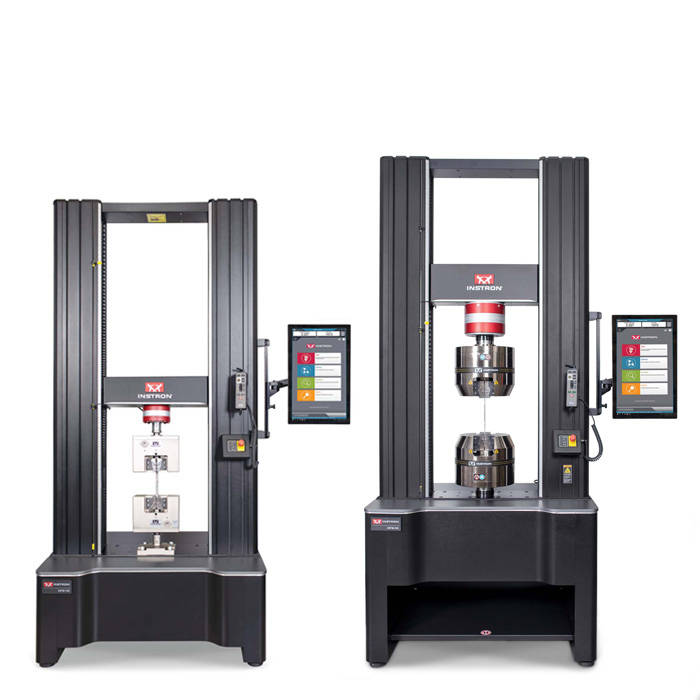

Static Testing

Up To 300 kN

Electromechanical universal testing systems can be equipped with a wide range of accessories to perform static tests when you need to determine the tensile, compressive, and flexure properties of a wide range of materials.

Learn More

Static Testing

Up To 2000 kN

Static hydraulic universal testing systems are commonly used for testing rebar, concrete, and other building materials with a testing range of 300 - 2000 kN force.

Static and Fatigue Testing

Up To 5000 kN

Our high capacity servohydraulic fatigue testing systems are used to characterize the fatigue life of high-strength materials to determine a products life cycle and provide insight into how a material will fail.

Now is the time to modernize your testing equipment. Instron offers multiple options for replacement of outdated parts and components, up to and including full replacement of your system. Instron’s system retrofits provide a comprehensive overhaul of your machine and replace all at-risk components, which rejuvenates your system and can extend its life for years. In cases where system replacement is preferable, our high force 6800 Series floor models and industrial series static hydraulic frames are available for testing up to 2,000 kN. Instron can also retrofit machines from other suppliers.

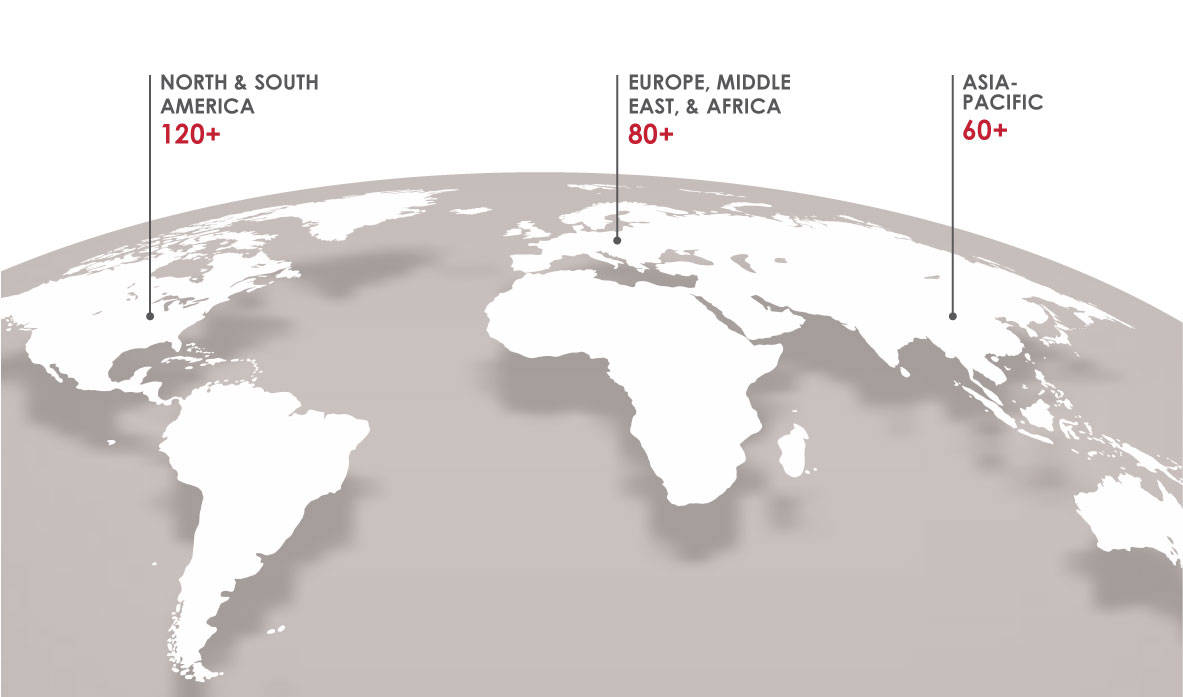

Instron has the strongest service and support team in the world, with over 250 field service engineers around the world. Our factory trained technicians can perform calibration and verification, installation, repair, and replacement services, as well as onsite technical support.